Intelligence and Green Total Factor Productivity Based on China’s Province-Level Manufacturing Data

Опубликована Апрель 29, 2021

Последнее обновление статьи Май 20, 2024

Abstract

The application of intelligent technology has an important impact on the green total factor productivity of China’s manufacturing industry. Based on the provincial panel data of China’s manufacturing industry from 2008 to 2017, this article uses the Malmquist–Luenburger (ML) model to measure the green total factor productivity of China’s manufacturing industry, and further constructs an empirical model to analyze the impact mechanism of intelligence on green total factor productivity. The results show that intelligence can increase the green total factor productivity of the manufacturing industry. At the same time, mechanism analysis shows that intelligence can affect manufacturing green total factor productivity by improving technical efficiency. However, the effect of intelligence on the technological progress of the manufacturing industry is not significant. In addition, the impact of intelligence has regional heterogeneity. It has significantly promoted the green total factor productivity in the eastern and central regions of China, while its role in the western region is not obvious. The research in this article confirms that intelligence has a significant positive impact on the green total factor productivity of the manufacturing industry, and can provide suggestion for the current further promotion of the deep integration of intelligence and the green development of the manufacturing industry to achieve the strategic goal of industrial upgrading.

Ключевые слова

Manufacturing, intelligent, green total factor productivity

1. Introduction

Since the reform and opening up, China’s economy has developed rapidly. In 2010, China became the world’s largest manufacturing country and showed a development trend of shifting from the low-end to the high-end. However, in the process of manufacturing upgrades, the production of enterprises consumed a large amount of resources and energy, and discharged a lot of waste gas, wastewater, and so on that caused serious damage and pollution to the environment. Therefore, the green transformation of the manufacturing industry is imminent, which means that it needs to take environmental and energy factors into consideration in the manufacturing process. The essence is to enhance the total factor productivity (TFP) of environmental, energy, and other factors, which is the green total factor productivity (GTFP), to make their contribution to the quality of the economic growth, which also means a double win for manufacturing economic performance and environmental performance. Green total factor productivity mainly focuses on the two aspects of total factor production and the green production. Total factor productivity mainly focuses on the efficiency of input and output, such as dynamic supply-chain management and enterprise operational performance, natural resources, and economic development [1,2]. Due to the excessive consumption of resources in economic development and the pollution caused by the production process, we must consider not only economic benefits, but also environmental benefits [3,4,5]. At the same time, the green development of manufacturing is the key to the synchronization of the “five modernizations”, and intelligent manufacturing is an important means to realize the green development of the manufacturing industry.

With the development of new global technological and industrial revolutions, intelligent manufacturing has become the main direction of the development of global manufacturing. In recent years, developed countries have successively launched manufacturing development strategies to cultivate new competitive advantages in manufacturing: the United States promulgated the “Advanced Manufacturing Partnership Program”, Germany implemented “Industry 4.0” development strategy, Japan proposed the “Industrial Value Chain” plan, and the United Kingdom implemented the “Industrial 2050 Strategy”. As can be seen, intelligent manufacturing has become the inevitable choice for the transformation and development of manufacturing industries and enhancing the competitiveness of manufacturing industries in various countries. Facing the new trend of manufacturing development, the Chinese government pays much attention to the development of intelligent manufacturing. The State Council issued the “Made in China 2025” strategy in 2015, which took intelligent manufacturing as the main direction. The Ministry of Industry and Information Technology and the Ministry of Finance jointly issued the “Intelligent Manufacturing Development Plan (2016–2020)”, which aimed to further accelerate the development of the manufacturing. Intelligent manufacturing is of great significance to facilitate the transformation of the manufacturing industry and the development of the manufacturing value chain to the mid-to-high end. At the same time, in the era of “Industry 4.0”, intelligent manufacturing also has an important impact on China’s economic growth.

There are many studies related to intelligence and manufacturing green development; however, there are few studies on how intelligence affects manufacturing GTFP. Does intelligence affect manufacturing GTFP, and if so, how? Does intelligence have different effects on the GTFP of the manufacturing in different regions? Using the provincial panel data of the manufacturing industry in China from 2008 to 2017, this paper studies the impact of intelligence on manufacturing GTFP and the different effects in different regions.

2. Literature Review

2.1. The Impact of Intelligence on the Economy

Intelligent manufacturing has become an important trend in the development of global manufacturing that has had an obvious effect on the social and economic development of human beings, and it has also become a research focus of scholars from all over the world. In recent years, scholars have conducted research on intelligence, mainly on the aspects of economic development.

Hanson established an exogenous growth model to study the impact of intelligence on the economy. The model assumed that machines have different effects on human labor at different stages. In the initial stage, machines and human labor complement each other, but eventually machines replace human labor on a large scale. The study also found that as the level of automation continued to improve, the economic growth rate also increased substantially [6]. Aghion et al. conducted research that showed that the application of intelligence accelerated the process of automation while promoting productivity. However, as the cost of nonautomated industries rises, the rate of return on capital will continue to decrease. Therefore, the impact of artificial intelligence on economic growth is not certain [7]. Agrawal et al. introduced the process of knowledge combination on the basis of Jones’ model to study the impact of artificial intelligence on economic growth. The results showed that artificial intelligence technology can significantly promote economic growth [8]. Clarke used the data of Australian listed companies from 2004 to 2008 to empirically study the relationship between industrial intelligence and corporate performance. The results showed that industrial intelligence can significantly improve corporate performance and enhance corporate competitiveness [9]. Laptev pointed out that intelligence can reduce enterprise costs and improve enterprise competitiveness. As the basic unit of the macro economy, the improvement of enterprise competitiveness will promote the development of the regional economy [10]. Artificial intelligence has a huge impact on technological innovation and economic development by improving the performance and innovation process of technology [11]. In some extreme cases, artificial intelligence may even rapidly self-improve and bring unlimited economic growth in a limited time [12].

2.2. Research on GTFP

The production of enterprises consumes a large amount of resources and energy, and discharges a lot of waste gas, wastewater and so on that cause serious damage and pollution to the environment. GTFP has attracted widespread attention, and many scholars have researched GTFP. Based on the meta-frontier theory and data envelopment analysis method, C Fang et al. calculated the green total factor productivity of extractive industries in China from 2006 to 2017, and analyzed its influencing factors [13]. Based on the comprehensive control method (SCM) using microdata, Jiang Yufan et al. studied the net impact of the establishment of China’s (Shanghai) pilot free trade zone on Shanghai’s green total factor productivity [14]. The study measured green total factor productivity (GTFP) to discuss whether factor market distortions inhibit the green development of China’s economy. Boqiang Lin et al. found that factor market distortion had a negative impact on China’s GTFP growth [15]. Wu used an SFA basic model to analyze the temporal and spatial dynamic evolution trend of marine economic green production efficiency in coastal areas of China [16]. D Liu et al. used the Super-SBM model to calculate China’s agricultural green total factor productivity. On this basis, the kernel density estimation method was used to study its dynamic evolution trend, and the panel data model was used to conduct empirical research on the influencing factors of China’s agricultural green total factor productivity [17]. Erdmann et al. studied the impact of ICT on greenhouse gas emissions through a scenario analysis, and found that in most scenarios, ICT reduced greenhouse gas emissions [18].

2.3. The Impact of Intelligence on the Total Factor Productivity

There are few studies on the impact of intelligence on green total factor productivity, and some have studied the impact of intelligent on production efficiency. Scholars’ research on the relationship between intelligence and TFP is mainly divided into two categories.

On the one hand, some scholars thought that intelligence can promote the growth of manufacturing TFP. Acemoglu and Restrepo studied the impact of automation on labor productivity and employment based on the theory of endogenous growth, and found that automation reduced the demand for labor through the use of cheap capital, and productivity was greatly improved [19]. Kromann et al. used panel data from 10 manufacturing industries in nine countries from 2004 to 2007 to study the impact of increased automation on productivity. The results showed that large-scale use of industrial robots had a significant effect on labor productivity [20]. Brynjolfsson et al. used survey data from 179 listed companies to analyze the impact of business practices and information-technology investment on production efficiency. The study showed that the output and productivity of companies that used data-driven decision-making were higher than for those that used other investment and information technologies by 5–6% [21]. Graetz and Michaels used panel data to empirically study the impact of automation on the economy. The research showed that the use of industrial robots significantly increased labor productivity, increasing GDP and labor productivity by 0.37% and 0.36%, respectively [22]. Feng Zhaokui researched the workshop of the Japanese automobile manufacturing industry and found that with the increasingly low price of robots, the ratio of robots replacing workers in production lines was increasing, which greatly reduced the labor required for daily production and improves labor productivity [23]. Commander et al. conducted research on companies in Brazil and India and found that information and communication technology had a positive effect on the productivity in both countries, and this effect was highly adaptable to different testing methods [24]. He Zhao et al. studied the application of AR/VR technologies in in the field of managing human resources (HRs) and basic operational corporate business processes. They found that AR/VR technologies could optimize business operation processes [25].

On the other hand, some scholars believe that intelligence has not significantly promoted total factor productivity development, or even inhibited such development. Cowen pointed out that the development of the Internet and computer technology does not promote productivity significantly. He believed that in the general perception, technological progress can effectively promote the increase of productivity. But when it comes to computer technology, this experience often turns out to be wrong [26]. Brynjolfsson et al. believed that there are four possible explanations for the artificial intelligence productivity paradox: false expectations, measurement errors, centralized distribution and rent dissipation, and implementation and restructuring delays [27]. Acemoglu and Restrepo pointed out that excessive automation is the main reason for suppressing productivity growth. Excessive automation not only directly leads to low production efficiency, but also may indirectly inhibit productivity growth through waste of resources and labor mismatch [28]. Acemoglu et al. made the research on the impact of the use of industrial robots in 19 industries on the U.S. labor market, and found that the large-scale application of industrial robots has a significant negative impact on employment and wages [29]. Stiroh conducted research based on the US manufacturing industry and believed that there was no evidence that the spillover effects of information technology would bring about total factor productivity growth [30].

Current literature contains rich research on intelligence and GTFP. However, there is a lack of direct research on the relationship between intelligence and the quality of economic development, and there are no studies on the relationship between intelligence and economic green development. Therefore, this article comprehensively considers the three factors of intelligence, economic development, and the environment, analyzes the internal mechanism of intelligence on the green development of the manufacturing industry, and provides a new perspective for the green transformation and upgrading of China’s economy. At the same time, this article studies the internal connection between the integrated development of “intelligence + manufacturing” and the transformation and upgrading of the manufacturing industry, which has important practical significance for improving the intelligence level of China’s manufacturing industry and promoting the green manufacturing industry.

3. Empirical Analysis and Research Hypothesis

3.1. Empirical Analysis

Regarding the development of GTFP and intelligence in China, Figure 1 shows the actual situation of GTFP and intelligence in China from 2008 to 2017.The specific calculation method will be introduced in detail below. As can be seen, GTFP and intelligence had similar trends from 2008 to 2017. At present, there are few studies of the relationship between intelligence and green total factor productivity in manufacturing at home and abroad, but studies related to Internet technology, information technology, and environmental protection found that the Internet and informatization are beneficial in promoting environmental protection. The Internet can improve environmental quality by reducing energy consumption and reducing pollution emissions. The use of the Internet is conducive to the reduction of energy intensity and the improvement of energy efficiency in the production sector, thereby reducing energy consumption [31,32]. The development of information and communication technology can suppress the level of carbon dioxide emissions, and the use of Internet platforms for transactions can reduce carbon dioxide emissions in developed countries [33,34]. We can make the hypothesis that intelligence has a positive relationship with GTFP.

where α and β are the contribution coefficients in intelligence and GTFP. We determined that α and β are both equal to 0.5, considering that they are both equally important in manufacturing, and interact equally within the system. G is the coupling degree of these two subsystems, V is the comprehensive index of these subsystems, and U is the coupling coordination degree of the system. According to the related research, U can be divided into four stages: 𝑈∈(0,0.3)𝑈∈(0,0.3), which indicates the low coordination stage; 𝑈∈(0.3,0.5)𝑈∈(0.3,0.5), which indicates the moderate coordination stage; 𝑈∈(0.5,0.8)𝑈∈(0.5,0.8), which indicates the high coordination stage; and 𝑈∈(0.8,0.1)𝑈∈(0.8,0.1), which indicates the extreme coordination stage.

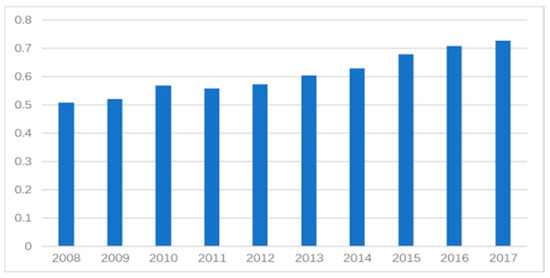

The degree of coupling coordination between the level of intelligence and the GTFP of the manufacturing industry is shown in Figure 2. In 2008, the coupling coordination degree of intelligent and GTFP was 0.501, which was in the middle coordination stage. In 2017, the coupling coordination degree of intelligence and GTFP was 0.726, which was in a highly coordinated stage. The degree of coupling and coordination from 2008 to 2017 exceeded 0.5, indicating that there was a close relationship between intelligence and the GTFP of manufacturing.

Considering the impact of intelligence on GTFP, it is essential to consider both the input and output aspects. Including capital, traditional labor production factors input and energy input. Output includes expected output GDP and undesired output environmental pollutant emissions. It is generally believed that the lower the input, the higher the expected output, and that lower undesired output means the GTFP increases faster. In addition, green total factor productivity can be divided into the forms of technical efficiency and technological progress [35,36,37]. Based on the Malmquist theory, this article analyzes the mechanism of the impact of intelligence on the GTFP of the manufacturing industry from the perspectives of technological progress and technical efficiency. This provides a realistic basis for our research on the relationship between intelligence and GTFP.

3.2. Research Hypothesis

3.2.1. Technical Efficiency Perspective

Intelligence can improve the single-factor productivity of enterprises. Advanced technology and management methods cannot directly increase the total factor productivity. Technology and management methods must accelerate the growth of total factor productivity by increasing the productivity of input factors. Intelligence improves the labor productivity of enterprises through the substitution effect and complementary effect of labor [38]. Companies use industrial robots to replace workers engaged in procedural and repetitive tasks, which saves labor input. At the same time, highly skilled labor and intelligence cooperate with each other. With the help of intelligent machine learning and automatic analysis, humans can complete tasks such as design faster, and improve work efficiency. Intelligence can reduce the depreciation rate of fixed assets of enterprises, improve the productivity of machines, and effectively promote the growth of the return on capital of enterprises. Compared with traditional automated machines, intelligent robots can continue to produce new products under the condition that the basic product structure remains unchanged, reducing the loss of capital on production equipment. In terms of machine production efficiency, intelligent machines optimize production processes through algorithm analysis and machine learning, simplifying production steps, and improving production efficiency.

Intelligence can improve energy efficiency and reduce energy consumption. Intelligent development has improved the production efficiency of manufacturing industries that promote the improvement of the efficiency of energy use in the manufacturing process. The improvement of energy efficiency means the reduction of energy consumption under the same output level. The reduction in energy consumption in manufacturing production also represents a reduction in input. The reduction of input under the same output also means an increase in green total factor productivity.

Intelligence improves the management level of an enterprise. Through an intelligent management system and decision-support system, the enterprise can effectively improve its operation management level and decision-making level, and realize efficient production management and operation management. Intelligence can predict market trends more accurately through big data analysis, scientifically arranging production plans, and always maintaining low inventory while meeting the market’s maximum demand. Intelligence has been monitoring all links of production, which improves the supervision and control ability of enterprises regarding the production process and product quality, and promotes the improvement of production efficiency. Intelligence can optimize the production plan of an enterprise, improve the quality of supervision and decision-making, and improve the technical production efficiency of enterprises.

3.2.2. Technological Progress Perspective

4. Model, Data, and Variables

4.2. Data Description

4.3. Variables Selection

4.3.1. Green Total Factor Productivity

Existing papers only considered the output of economic benefits when measuring total factor productivity. However, with the intensification of environmental pollution, only considering economic benefits may lead to a misleading evaluation of economic performance and social welfare [40]. Therefore, considering the expected output and the undesired output at the same time can result in a more accurate measurement of economic and social development [41]. According to the above analysis, we incorporated the expected output and undesired output into the productivity framework, and constructed the Malmquist–Luenburger (ML) index to measure GTFP. The formula is as follows:

If the values of the ML index, EFF, and TECH are greater than 1, it means that from t to t + 1, the level of GTFP, technical efficiency, and technological progress have been increased, otherwise it is reduced (less than 1) or unchanged (equal to 1).

In the actual measurement process, we need to set the corresponding input variables and output variables in advance [42,43]. In terms of input variables, we chose the fixed asset investment in the manufacturing industry, the number of employees in the manufacturing industry in each province, and the standard coal consumption in each province in China as input indicators from 2008 to 2017.They represent capital investment, personnel investment, and energy investment, respectively. As output variables, we mainly included expected output and undesired output. We used the manufacturing GDP of each province to express the expected output. As the undesired outputs, we used industrial sulfur dioxide (SO2) emissions, wastewater disposal, and solid waste.

4.3.2. Intelligence

4.3.3. Control Variables

In this research topic, other control variables that may affect GTFP include foreign direct investment, economic level, urbanization, and regional human capital. (1) For foreign direct investment, we selected foreign investment of the provinces from 2008 to 2017 as the indicator; (2) for economic level, we chose the regional GDP of the provinces from 2008 to 2017 as the indicator to express this; (3) the level of urbanization (Urb) was expressed by the ratio of the urban population to the total population of a province; and (4) the level of human capital was based on the full-time equivalent of R&D personnel in the region. Table 1 lists the descriptive statistical results of all the above variables.

5. Results and Discussion

5.1. The Impact of Intelligence on Green Total Factor Productivity

In order to comprehensively analyze the impact of intelligence on the GTFP of China’s manufacturing, and to explore the source of manufacturing GTFP changes, the empirical analysis of this paper was mainly divided into two parts: On the one hand, intelligence affects the overall regression of China’s manufacturing GTFP, and the regression of the GTFP decomposition item. On the other hand, this paper analyzes the influence of intelligence on the GTFP of manufacturing in China’s eastern, central, and western regions, and explores the regional heterogeneity of intelligence on the GTFP of China’s manufacturing industry. This study used Eviews10 to estimate the model; the results are shown in the Table 2.

According to Table 2, it can be found that intelligence had a positive and significant impact on the GTFP and technical efficiency of the manufacturing industry, and had a negative impact on technical progress. This showed that intelligence can effectively promote the growth of GTFP in manufacturing, which verified the theoretical hypothesis of this article. Intelligence promotes technical efficiency but inhibits technological progress. This may be because China’s current manufacturing enterprises are more inclined to use intelligent technology to improve production efficiency, ignoring the technological upgrading of manufacturing through intelligence. Intelligence had a positive impact on GTFP and technical efficiency, and had a negative impact on technical progress. This was similar to the conclusions drawn by scholars such as Adler that from the perspective of modern economic development worldwide, all economies lack industries with rapid technological advancement. This is not because of lack of technological innovation opportunities, but because of lack of technological innovation incentives [44,45].

According to the other control variables, the impact of foreign investment on the GTFP of manufacturing was negative. This may be due to the transfer of industrial chains by Western developed countries and the transfer of more polluting industries to developing countries and regions, which causes developing countries and regions to face the dilemma of environmental pollution. The impact of GDP on manufacturing GTFP and technical efficiency was both positive and significant, while the impact on technological progress was not significant, indicating that economic development promoted the growth of GTFP in manufacturing by improving manufacturing technical efficiency. Urbanization had a negative impact on manufacturing GTFP, which indicated that the quality of urbanization was low. On the one hand, the excessive concentration of population in big cities made the flow of economic factors unbalanced. On the other hand, the rapid progress of population urbanization increased the pressure on the urban ecological environment. The impact of R&D human capital on manufacturing GTFP and technical progress was positive and significant, but the impact on technical efficiency was not significant, indicating that R&D human capital promoted the growth of GTFP by promoting manufacturing technical progress.

5.2. Heterogeneity Analysis

In order to explore the heterogeneity of the impact of intelligence on the GTFP of manufacturing in the three major regions of China’s east, middle and west, we conducted a regression analysis with sample data from those regions. The specific regression results are shown in Table 3.

Table 3. Regression results of eastern, central, and western regions of China.

According to Table 3, due to the different levels of economic and social development in the eastern, central, and western regions, the impact of intelligence on the green total factor productivity of manufacturing in different regions was also different. This conclusion was similar to that of the current papers [46,47,48].

It was found that intelligence had a positive and significant impact on the GTFP and technical efficiency of manufacturing in the eastern region, while the impact on the technical progress was not significant. Intelligence promoted the GTFP of manufacturing in the eastern region by improving the technical efficiency of manufacturing. This was mainly due to the fact that the manufacturing industry in eastern China mainly uses intelligent technology to improve the production efficiency of the manufacturing industry, instead of promoting technological upgrading through intelligent technology.

The impact of intelligence on the GTFP and technical efficiency of the manufacturing industry in the central region was positive and significant, and the impact on technological upgrading was not significant. This showed that the effect of intelligence on the GTFP of manufacturing in the central region was achieved by improving the technical efficiency of manufacturing enterprises in the central region. Compared with the eastern region, the development of manufacturing industry in the central region was underdeveloped. The application of intelligence in the manufacturing industry effectively promoted the improvement of the technical efficiency of manufacturing enterprises. Intelligence had no significant impact on the technological progress of the central region, which may be due to the low level of intelligence in this region.

Intelligence had no significant impact on the GTFP of manufacturing in the western region. This showed that intelligence has no obvious promotion effect on the GTFP of the manufacturing industry in the western region, the main reason for which was that the application of intelligence in the manufacturing industry in the west was still in its infancy at this stage, and the manufacturing industry in the west was still in the underdeveloped stage, and had a large gap between the manufacturing industries in the central and eastern regions.

Based on the analysis of the regression results of the whole country and the eastern and central regions, it was found that intelligence promoted the GTFP of manufacturing in the eastern and central regions by improving technical efficiency, and that intelligence had no significant effect on the improvement of technological progress. This is mainly because Chinese manufacturing companies use intelligent technology mainly at the application level, rather than for industrial upgrading and innovation.

5.3. Robustness Test

In order to consider the potential impact of the selection of variable indicators on the research results, and to ensure the reliability and stability of the research results, we measured intelligence from the perspective of output, and tested the robustness of the model. We used the total software business revenue to replace intelligence, while other variables remained unchanged.

According to a comparison of Table 2, Table 3 and Table 4, it was found that the variable signs and significance of the national overall and subregional regression results were basically unchanged, indicating that the national overall and subregional regression results were relatively stable; that is, intelligence promoted manufacturing GTFP through technical efficiency.

Table 4. Regression results of robustness tests.

6. Conclusions and Policy Implications

There have been numerous studies on intelligence, many of which focused on the impact of intelligence on economic development [6,7,8,9,10,11,12] and production efficiency [19,20,21,22,23,24,25,26,27,28,29,30]. They mainly studied the impact of intelligence on economic development, without considering environmental and energy factors. In the process of economic development, energy may be excessively consumed, and the environment may be polluted in the process of production. This has a negative impact on social development. Unlike these papers, this paper took environmental factors into consideration.

Using the panel data of 29 provinces in the China mainland from 2008 to 2017, this paper used the Malmquist–Luenburger model to measure China’s manufacturing GTFP. The paper analyzed the impact of intelligence on the GTFP, technical efficiency and technological progress of China’s manufacturing industry from the perspectives of the entire country and the east, middle, and west regions. The research conclusions of this paper have three main points. First, intelligence promotes the development of GTFP in manufacturing by improving technical efficiency. Second, intelligence had a heterogeneous effect on the eastern, central, and western manufacturing industries. It had a significant promotion effect on the GTFP of the manufacturing industry in the eastern and central regions, but had little effect on the GTFP of the western manufacturing industry. Third, in the whole country and in the eastern, central, and western regions, intelligence had no significant promotion effect on technological progress. This is because manufacturing companies develop intelligent technologies mainly to increase productivity to increase profits.

Intelligence promotes the development of GTFP in manufacturing by improving technical efficiency. This is due to improving production efficiency through intelligent technology, which can reduce labor costs and increase profits for enterprises in the short term. The allocation of a large amount of funds and human capital to the R&D department may cause a decline in the output of the production department in the short term and increase the operating cost of the enterprise. The enterprise pays too much attention to the deviation of intelligent technology development caused by the increase of short-term output and profit. Intelligence had different effects on the GTFP of manufacturing in different regions. This is due to the differences in the level of intelligence and manufacturing development in China’s east, middle, and west regions.

The policy implications of this article mainly had the following three aspects.

First, as the main direction of “Made in China 2025”, green development needs to rely on the positive effects of intelligence. On the one hand, we must take “Made in China 2025”as the guide, gradually promote the implementation of manufacturing intelligent, and continuously improve the support capacity of intelligence by promoting innovation in the new generation of intelligent technologies. On the other hand, we must focus on promoting the transformation and upgrading of the manufacturing industry, accelerate the integration of intelligence and industrialization, and continuously improve the application and innovation capabilities of intelligence in the manufacturing industry.

Second, the impact of intelligence on the GTFP of manufacturing in different regions was different. But the influence of intelligence on the GTFP of manufacturing in the western region was not significant, mainly due to the underdeveloped level of manufacturing in that region. As the western ecological environment is relatively fragile, intelligence plays an important role in protecting the western ecological environment. The government should increase its support for intelligence and manufacturing in the western region, raise the level of technology within the region, improve management methods, and ameliorate the factor endowment structure.

Third, according to the research in this article, intelligence affects the GTFP of the manufacturing industry through efficiency improvement. The impact of intelligence on technological progress was not significant. We concluded that enterprises mainly use intelligent technology to increase productivity, and pay little attention to technological progress. So, the government and enterprises should increase their research on intelligence and increase research efforts to break through core technologies to promote technological progress. The government should encourage manufacturing enterprises to reduce environmental pollution and save resources by improving technology upgrades and improving technical efficiency, and use intelligence to accelerate the construction of a green and low-carbon industrial system, so as to promote the transformation of manufacturing from high energy consumption and high pollution to a low energy consumption and low pollution development mode. R&D personnel play an important role in promoting the level of intelligent development in China, and the government must strongly support the training of intelligent R&D personnel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mekhum, W. The impact of sustainability concept on supply chain dynamic capabilities. Pol. J. Manag. Stud. 2019, 20, 267–276. [Google Scholar] [CrossRef]

- Haseeb, M.; Kot, S.; Iqbal-Hussain, H.; Kamarudin, F. The natural resources curse-economic growth hypotheses: Quantile-on-Quantile evidence from top Asian economies. J. Clean. Prod. 2021, 279, 123596. [Google Scholar] [CrossRef]

- Nielsen, I.E.; Majumder, S.; Szwarc, E.; Saha, S. Impact of Strategic Cooperation under Competition on Green Product Manufacturing. Sustainability 2020, 12, 248. [Google Scholar] [CrossRef]

- Dey, K.; Saha, S. Influence of procurement decisions in two-period green supply chain. J. Clean. Prod. 2018, 190, 388–402. [Google Scholar] [CrossRef]

- Nielsen, I.E.; Majumder, S.; Saha, S. Exploring the intervention of intermediary in a green supply chain. J. Clean. Prod. 2019, 233, 1525–1544. [Google Scholar] [CrossRef]

- Hanson, R. Economic Growth Given Machine Intelligence; Technical Report; University of California: Berkeley, CA, USA, 2001. [Google Scholar]

- Aghion, P.; Jones, B.F.; Jones, C.I. Artificial Intelligence and Economic Growth. NBER Chapters. No. 23928. 2017. Available online: https://ideas.repec.org/h/nbr/nberch/14010.html (accessed on 16 October 2017).

- Agrawal, A.; Gans, J.; Goldfarb, A. Prediction, Judgement, and Complexity. NBER Working Paper No. w24243. 2018. Available online: https://doi.org/10.3386/w24243 (accessed on 22 March 2021).

- Clarke, M.; Seng, D.; Whiting, R.H. Intellectual capital and firm performance in Australia. J. Intellect. Cap. 2011, 12, 505–530. [Google Scholar] [CrossRef] [Green Version]

- Laptev, V.A. Artificial Intelligence and Liability for Its Work. Law J. Higher Sch. Econ. 2019, 79. [Google Scholar] [CrossRef]

- Kromann, L.N.; Malchow-Møller, N.; Skaksen, J.R.; Sorensen, A. Automation and Productivity—A Cross-Country, Cross-Industry Comparison. Ind. Corp. Chang. 2020, 29, 265–287. [Google Scholar] [CrossRef]

- Nordhaus, W.D. Are We Approaching an Economic Singularity? Information Technology and the Future of Economic Growth; NBER Working Papers; National Bureau of Economic Research: Cambridge, MA, USA, 2015. [Google Scholar]

- Fang, C.; Cheng, J.; Zhu, Y.; Chen, J.; Peng, X. Green Total Factor Productivity of Extractive Industries in China: An explanation from Technology Heterogeneity. Resour. Policy 2020. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, H.; Liu, Z. The impact of the free trade zone on green total factor productivity—Evidence from the shanghai pilot free trade zone—ScienceDirect. Energy Policy 2021, 148, 112000. [Google Scholar] [CrossRef]

- Lin, B.; Chen, Z. Does factor market distortion inhibit the green total factor productivity in China? J. Clean. Prod. 2018, 197, 25–33. [Google Scholar] [CrossRef]

- Wu, D. Impact of Green Total Factor Productivity in Marine Economy Based on Entropy Method. Pol. Marit. Res. 2018, 25, 141–146. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Zhu, X.; Wang, Y. China’s agricultural green total factor productivity based on carbon emission: An analysis of evolution trend and influencing factors. J. Clean. Prod. 2020, 278, 123692. [Google Scholar] [CrossRef]

- Erdmann, L.; Hilty, L.M. Scenario Analysis Exploring the Macroeconomic Impacts of Information and Communication Technologies on Greenhouse Gas Emissions. J. Ind. Ecol. 2010, 14, 826–843. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. The Race between Machine and Man: Implications of Technology for Growth, Factor Shares and Employment. Am. Econ. Rev. 2018, 108, 1488–1542. [Google Scholar] [CrossRef] [Green Version]

- Kromann, L.; Skaksen, J.R.; Sorensen, A. Automation, Labor Productivity and Employment: A Cross Country Comparison. SSRN Electron. J. 2016. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Hitt, L.M.; Kim, H.H. Strength in Numbers: How does data-driven decision—Making affect firm performance? Int. Conf. Inf. Syst. 2011. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Robots at Work: The Impact on Productivity and Jobs. Centre Piece-The Magazine for Economic Performance. 2015. Available online: http://cep.lse.ac.uk/pubs/download/cp447.pdf (accessed on 29 April 2021).

- Zhaokui, F. Dialectical analysis of the impact of robots on the Japanese economy. Jpn. J. 2016, 3, 73–96. (In Chinese) [Google Scholar]

- Commander, S.; Harrison, R.; Menezes-Filho, N. ICT and Productivity in Developing Countries: New Firm-Level Evidence from Brazil and India. Rev. Econ. Stat. 2011, 93, 528–541. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, Q.H.; Ślusarczyk, B. Sustainability and Digitalization of Corporate Management Based on Augmented/Virtual Reality Tools Usage: China and Other World IT Companies’ Experience. Sustainability 2019, 11, 4717. [Google Scholar] [CrossRef] [Green Version]

- Tyler, C. The Great Stagnation: How America Ate All the Low-Hanging Fruit of Modern History, Got Sick, and Will (Eventually) Feel Better. Survival 2012, 53, 190–191. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Rock, D.; Syverson, C. Artificial Intelligence and the Modern Productivity Paradox: A Clash of Expectations and Statistics. NBER Working Papers. 2017. Available online: https://doi.org/10.3386/w24001 (accessed on 22 March 2021).

- Acemoglu, D.; Restrepo, P. Artificial Intelligence, automation and work. Soc. Sci. Electron. Publ. 2018. [Google Scholar] [CrossRef] [Green Version]

- Acemoglu, D.; Restrepo, P. Robots and Jobs: Evidence from US Labor Markets. NBER Working Papers. 2017. Available online: https://doi.org/10.2139/ssrn.2940245 (accessed on 22 March 2021).

- Stiroh, K.J. Are ICT Spillovers Driving the New Economy? Rev. Income Wealth 2002, 48, 33–57. [Google Scholar] [CrossRef]

- Romm, J. The internet and the new energy economy. Fuel Energy Abstr. 2003, 44. [Google Scholar] [CrossRef]

- Wang, D.; Han, B. The impact of ICT investment on energy intensity across different regions of China. J. Renew. Sustain. Energy 2016, 8, 055901. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Liu, C. The Impact of ICT Industry on CO2 Emissions: A Regional Analysis in China. Renew. Sustain. Energy Rev. 2015, 44, 12–19. [Google Scholar] [CrossRef]

- Almulali, U.; Sheauting, L.; Ozturk, I. The Global Move Toward Internet Shopping and Its Influence on Pollution: An Empirical Analysis. Environ. Sci. Pollut. Res. 2015, 22, 9717–9727. [Google Scholar] [CrossRef]

- Chang, T.P.; Hu, J.L. Total-factor energy productivity growth, technical progress, and efficiency change: An empirical study of China. Appl. Energy 2010, 87, 3262–3270. [Google Scholar] [CrossRef]

- Peng, J.; Xiao, J.; Wen, L.; Zhang, L. Energy industry investment influences total factor productivity of energy exploitation: A biased technical change analysis. J. Clean. Prod. 2019, 237, 117847. [Google Scholar] [CrossRef]

- Cheng, Z.; Jin, W. Agglomeration Economy and the Growth of Green Total-Factor Productivity in Chinese Industry. Socio-Econ. Plan. Sci. 2020. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Cheng, Z. China Manufacturing Development Research Report 2019: 40 Years of Made in China and Intelligent Manufacturing; Beijing Science Press: Beijing, China, 2019; pp. 156–158. [Google Scholar]

- Hou, S.; Song, L. Market Integration and Regional Green Total Factor Productivity: Evidence from China’s Province-Level Data. Sustainability 2021, 13, 472. [Google Scholar] [CrossRef]

- Li, J.; Zhu, C.; An, L. Historical changes and regional differences in the performance of China’s economic low-carbon transition. China Soft Sci. 2013, 5, 167–182. (In Chinese) [Google Scholar]

- Pittman, R.W. Multilateral Productivity Comparisons with Undesirable Outputs. Econ. J. R. Econ. Soc. 1983, 93, 883–891. [Google Scholar] [CrossRef]

- Chen, S.; Golley, J. ‘Green’ productivity growth in China’s industrial economy. Energy Econ. 2014, 44, 89–98. [Google Scholar] [CrossRef]

- Wan, L.; Zhu, Q. The impact of R&D input on the growth of industrial green total factor productivity—Empirical data from China’s industry from 1999 to 2010. Econ. Trends 2013, 9, 20–26. (In Chinese) [Google Scholar]

- Adler, G.; Duval, M.R.A.; Furceri, D.; Çelik, K.S.; Koloskova, K.; Ribeiro, M.P. Gone with the Headwinds, Global Productivity, IMF Staff Discussion Notes. 2017. [CrossRef]

- Woetzel, J.; Seong, J.; Leung, N.; Ngai, J.; Manyika, J.; Madgavkar, A.; Lund, S.; Mironenko, A. China and the World: Understanding the Changing Economic Links; McKinsey Global Institute: NewYork, NY, USA, 2019. [Google Scholar]

- Li, H.; Hu, J.; Zhang, W. Regional Differences between the Rate of Change of CO2 Emission Intensity of Chinese Provinces and Implications for Sustainable Development. Sustain. Dev. 2018. [Google Scholar] [CrossRef]

- Wu, H.; Hao, Y.; Ren, S. How do environmental regulation and environmental decentralization affect green total factor energy efficiency: Evidence from China. Energy Econ. 2020, 104880. [Google Scholar] [CrossRef]

- Cieślik, A.; Michałek, J.J.; Nasadiuk, I. The Regional Heterogeneity of Productivity Determinants: Evidence from Ukrainian Firms. Misc. Geogr. Reg. Stud. Dev. 2017, 21. [Google Scholar] [CrossRef] [Green Version]