Tribological performance of surface texturing in mechanical applications—a review

Published: Jan. 1, 2020

Latest article update: Nov. 18, 2022

Abstract

Surface textures have been of great interest within the tribology community with nearly 1500 papers published on this topic in the past two decades. With the pursuit of low emissions and environmental sustainability, the application of surface texturing to mechanical systems to lower friction and control wear is attracting increasing attention. There is no doubt that certain textured surfaces can have a beneficial effect on tribological performance but it is widely agreed that the optimization of textures should be carried out based on specific requirements of applications. The purpose of this review article is to summarize the current state of the art in surface texturing applied to mechanical applications (cutting tools, piston-ring & cylinder liners, sealing and journal bearings) from the following aspects: application requirements, numerical/experimental testing and validation, and tribological performance of textured surfaces (wear and friction), as well as the limitations in texture designs when applied to certain applications. Patterns/grooves in the micron-scale are the most typical shapes been studied, and benefits of partial texturing are applicable for most of these mechanical applications. Friction reduction of up to 34.5% in cutting tools, 82% in piston-ring & cylinder-liners, 65% in seals and 18% in journal bearings have been observed by experimental tests. Based on primary evidence from the literature, the last section provides general suggestions on current gaps in understanding and modelling and suggestions for future research directions.

Keywords

Mechanical applications, surface texturing, tribological performance

1. Introduction

Friction and wear are very important parameters for assessing tribological performance of mechanical applications, and surface finish plays a significant role in influencing both parameters. Extensive studies have been conducted on surface modifications to achieve beneficial tribological performance, and surface texturing has been identified as one of these methods and that it has attracted a great deal of attention recently. In most tribological studies and applications, the term ’surface texturing’ refers to producing artificial surfaces with regular asperities that have determined shape, size and distribution. Typically, engraving/ carving methods are used to produce negative textures (individual spots or narrow channels) and projecting methods are used to produce positive textures (asperities). This review paper will only focus on the discrete negative features and, more specifically, their application to mechanical systems.

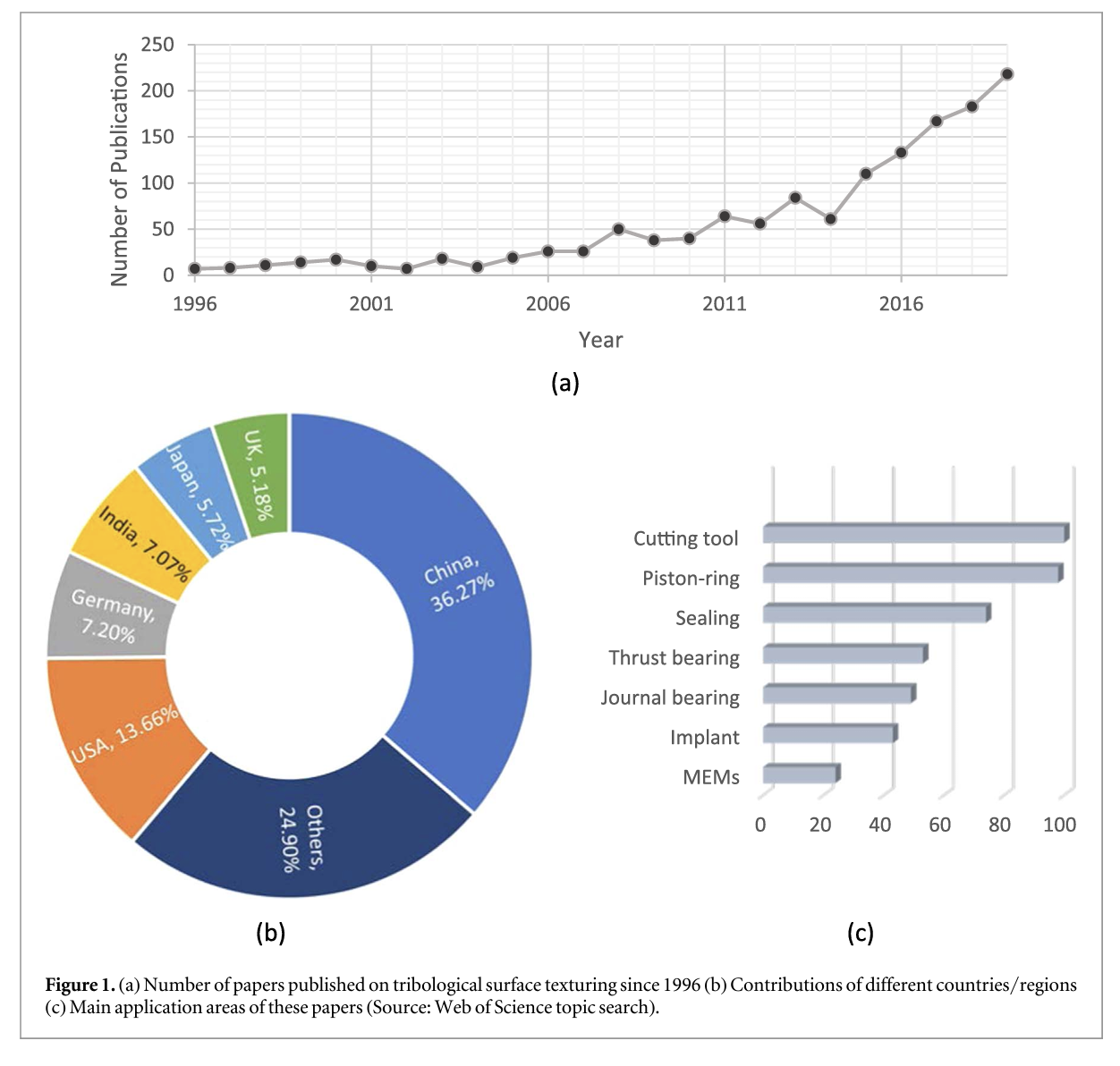

More than 99% of the research on surface textures have been conducted in the last two decades, driven by the promising modelling results obtained by Etsion’s group in 1996. They found that the sealing performance of a mechanical seal was significantly improved when hemispherical micro-dimples were evenly distributed on one of the mating sealing surfaces [1]. As shown in figure (a), the research on tribological studies using surface texturing is still drawing increasing attention, and figure 1(b) shows the top six countries contributed the most research on this topic.

Due to the beneficial results observed by researchers, surface texturing is being actively studied and has the potential to be used in numerous tribological applications [2]. Take diesel engines for example, where the pistons and cylinders are operating at high temperatures, high loads and high speeds. Lubricant starvation in these contacts causes severe scuffing, which eventually can lead to seizure and failure. To address this problem, surface texturing has been used in the diesel engine piston ring-linear interfaces since the 1940s to prevent seizure from occurring [3]. And until now, cross-hatched honing grooves are still being used in on cylinder liners of modern diesel engines [4].

There is no doubt that certain textured surfaces can have a beneficial effect on tribological performance enhancement, and considerable research has been done to study the function of textures in various working conditions, see figure 1 (c). It should be noted that the function of textures and optimal texturing parameters are very dependent on the type of contact between tribo-pairs (parallel, wedged, line or point contacts) and the operating conditions [5]. There is no universal selection of the texture parameters that could generate beneficial effects for different working conditions. For certain contacts or working conditions (i.e. high-pressure, non-conformal contacts), the benefit of surface texturing is negligible and may even become detrimental. Therefore, the design process of surface texturing is highly relevant to the functionality requirements of specific applications [6], and the studies focused on specific applications are extremely valuable for future industrial design and development.

This paper aims to review four successful mechanical applications (cutting tools, piston-rings, sealing and journal bearings) from the following aspects: application requirements, numerical/experimental testing and validation, and tribological performance of textured surfaces (wear and friction), as well as limitations in texture designs as seen in certain applications. Although thrust bearings are listed as a high-frequency keyword in literature searches, papers on are actually focused on this application are very limited and therefore will not be included in this paper. In addition, this review will look at single size features rather than hierarchical and multiscale features such as biomimetic surfaces.

2. Background

2.1. Mechanisms of performance enhancement

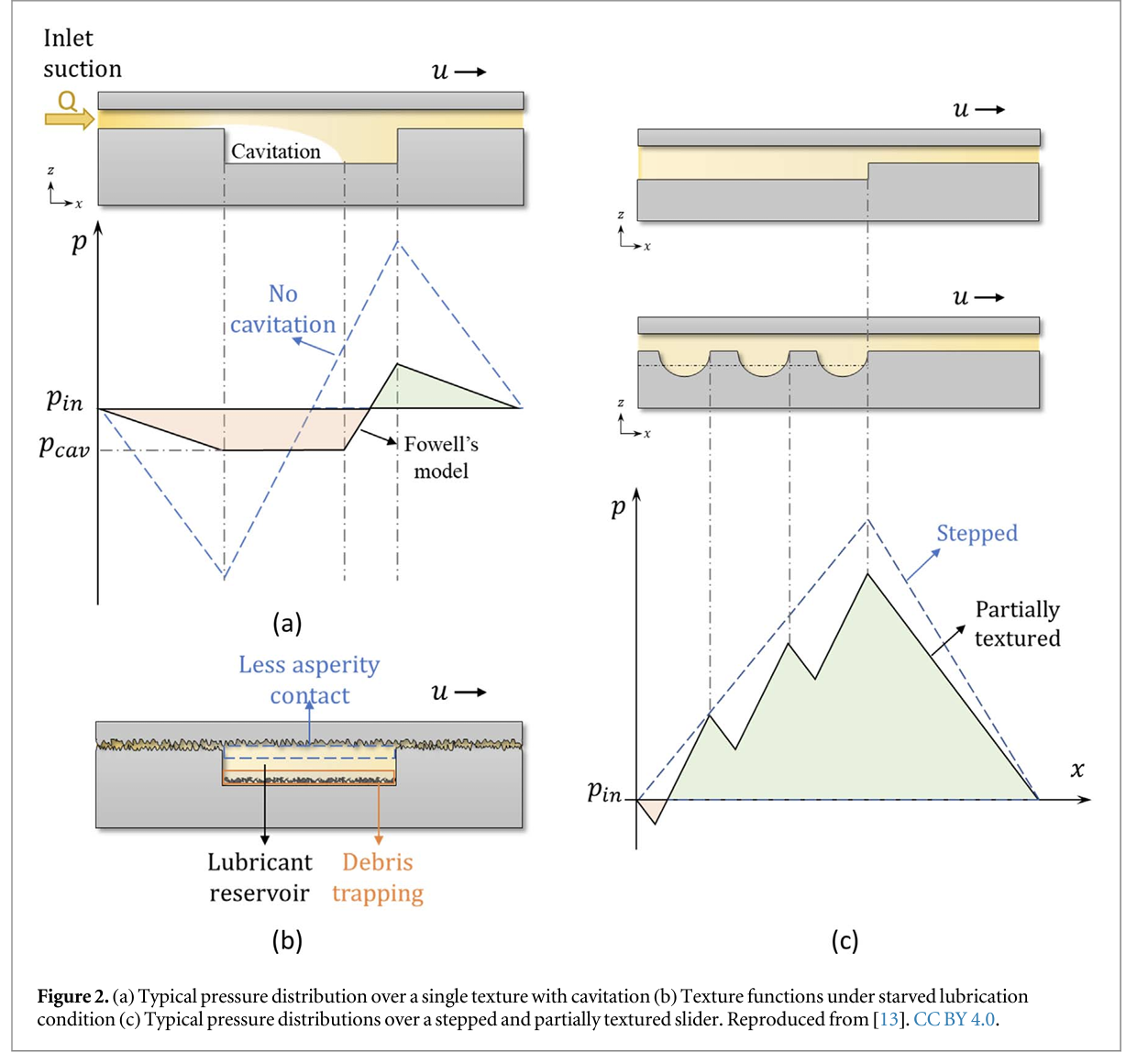

For tribological applications under hydrodynamic lubrication, the fluid film thickness and the roughness of the solid surfaces determines the lubrication regime and friction/traction levels. The main target for reducing friction and wear under this condition is to maintain the lubrication film thickness at a certain level, so that the solid surfaces can be entirely separated from each other. In 1966, Hamilton et al and coworkers found micro-irregularities act as microhydrodynamic bearings for generating additional hydrodynamic pressures that result in higher loadcarrying capacity, which means the lubrication system can support higher loads without failure or excessive wear. Cavitation was observed at the divergent part of micro-irregularities in a transparent rotor, which was suggested to be the responsible mechanism for the enhanced load support [7]. Later work by Anno shows this mechanism is well suited for fluid lubricated conformal contact applications such as mechanical face seals and parallel rotating thrust bearings [8, 9]. Powell and Olver et al stated that if a pocket operates under a supply pressure which exceeds the lubricant cavitation pressure, see figure (a), more lubricant can be sucked into the contact zone (inlet suction) [10,11]. It is important to note that improper selection of texture parameters (i.e., texture depth, width, and density) may lead to excessive cavitation, resulting in adverse effects such as localized film thickness and reduced load-carrying capacity [12].

Partially texturing effects, see figure (c), were studied by Etsion’s group that partial distributed circular dimples can generate ‘collective’ effect. Each dimple strongly affects its neighbouring dimples, which results in a step-like pressure distribution over the textured zone, and behaves similarly to a Rayleigh step bearing [14]. The concept of partial texturing is a rather conventional approach to enhance load support, and this is particularly important for contacts with parallel or flat surfaces, such as flat piston rings and mechanical seals, which will be discussed in the following sections.

Apart from the function of influencing pressure distribution within lubricant films, the texture feature could also serve as microtraps for wear debris and micro-reservoirs for lubricant, see figure 2(b). In 1984, Suh and co-workers tested modulated surface built by etching technique at sliding contacts, and they found the oxide wear debris at the interface of electrical contacts were trapped in the undulation, thereby reducing the ploughing and deformation caused by the debris [15]. The function of microtraps worked in either lubricated or dry conditions [16]. In cases of starved lubrication conditions or grease and solid lubricants, surface textures also act as lubricant micro-reservoirs that store and supply lubricant to the contact surfaces [7, 17]. Moreover, the overall contact area is smaller due to the existence of textures, which results in less asperity contact and therefore less adhesion/abrasion [18, 19].

In summary, there are mainly five basic beneficial effects of surface texturing:

- Under all lubrication conditions, textures can capture wear particles during normal wear with debris size ranges from 1-20 pirn (debris trapping effect) [16].

- Under hydrodynamic lubrication, textures function as micro-hydrodynamic bearings which boost the dynamic fluid pressure thus increasing the overall load-carrying capacity (micro-hydrodynamic effect) [20]. In terms of pressure distribution, partially textured surface behaves similarly to a Rayleigh step bearing [21].

- Under hydrodynamic lubrication, textures entrain additional lubricant into the contact area when the supply pressure in excess of the lubricant cavitation pressure (inlet suction effect) [10,11].

- Under mixed to boundary lubrication conditions, texture features act as reservoirs and supply lubricant to the interface (oil storage effect) [7,17].

- Under mixed to dry friction, textures lower the overall contact area and thus friction [18,19].

Other functions subject to individual applications will be discussed in the following sections.

2.2. Texturing parameters

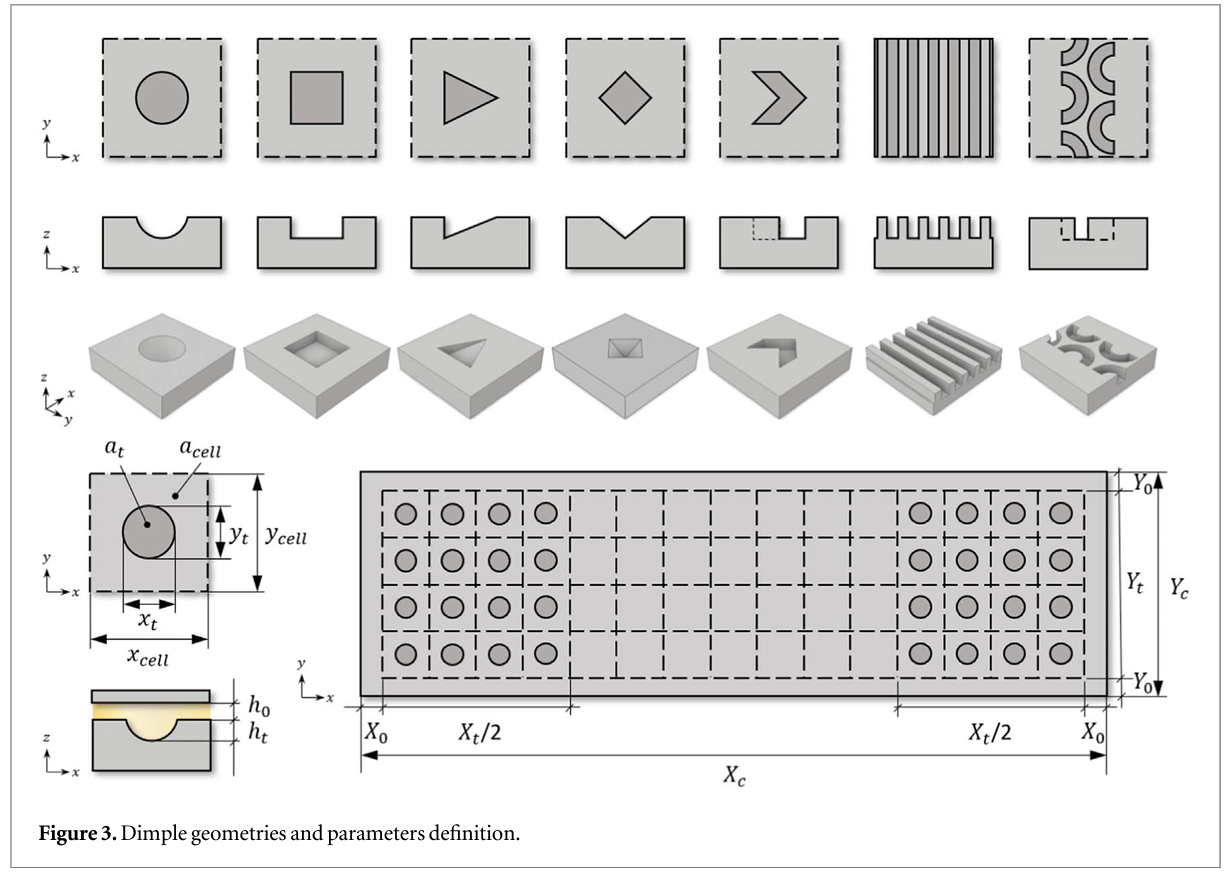

Various parameters have been used to describe dimple geometries, see figure 3, a single texture is characterized by its three-dimensional shape (basic shape and internal structure/bottom contour), dimensions (basic size and depth), and, in the case of asymmetric textures, its orientation relative to the sliding direction. There are also definitions about the open and close pockets, open pockets are usually referring to pockets that are adjacent to contact edges or cannot be completely covered within the Hertzian contact area, instead, closed pockets are completely covered within the contact. The most widely used parameters for a general feature include; texture size (xt, yt), texture depth (ht), texture area (at), cell size (xcdh ycdl), cell area (aceB = хсец x ycd!), texture aspect ratio (At = xt/xceu or yt/ycdl)> minimum film thickness (h0), relative dimple depth (S = h0 /%), texture density for uniformly distributed textures (pt = at/асец), for partially texture design, a textured contact can be further described by its relative textured portion (Xt, Yt), texturing position (Xo, Yq) among the contact area with contact dimension (Xc, Yc). A lot of fundamental research has focused on these parameters to find whether there are optimal values for the best friction reduction effect over various lubrication regimes, or any straightforward and direct relationship between the specific parameter and frictional results [18,22].

2.3. Texturing techniques

With the development of advanced fabrication techniques including additive manufacturing over the years, complicated texture designs become more achievable with great precision, repeatability, efficiently and cost- effectively. The texture features are not limited to common geometries such as circular dimples and grooves, a mixture or overlapped features with various geometries and scales can be produced on the same function surface, such as hierarchical structures of bio-inspired surfaces [23]. As described in a comprehensive review by Costa, texturing methods can be broadly divided into four categories: adding material, removing material, material displacement and selfforming methods [24]. Benefits, limitations and the target applications of the most widely used techniques are well summarized by Arslan [25]. The choice of the texturing method for certain applications has to meet the minimum standards such as compatibility with the dimensions of the workpiece, compatibility with the required shape and grain size, accuracy, safety of the substrate material, productivity and cost- effectiveness [26]. Table 1 summarises the principle of the most widely used techniques in tribological studies, and the materials been textured, as well as the feature scales they can achieve.

3. Successful cases in mechanical applications

3.1. Cutting tool

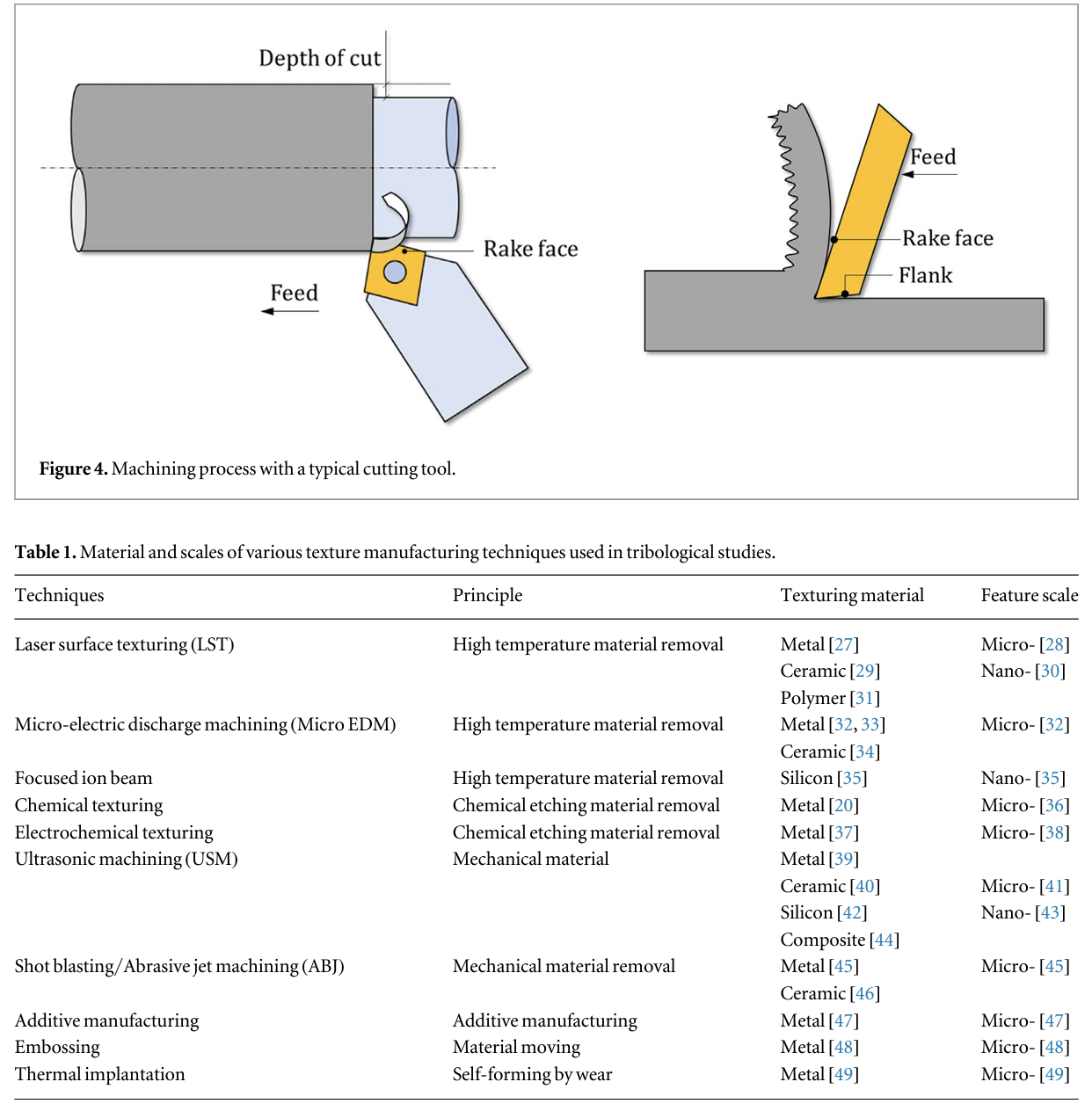

The metal cutting process is one of the most important and essential parts of manufacturing. Various types of tool materials, from high carbon steels to cemented carbides, ceramics and diamond (natural and synthetic), are used to make cutting tools (drill bits, tool bits, milling cutters, etc). It is important to be aware of the differences between these tool materials and the proper usage of each material. Hardness, toughness and wear resistance are essential characteristics of cutting tools. As shown in figure 1, progressive wear of the cutting tool occurs where the tool is in contact with the workpiece, i.e. on the rake face and the tool flank. The friction, wear, and adhesion of chip and cutting forces in cutting operations are highly related with the finish quality of machined parts, problems such as high cutting forces and serious tool wear will result in a poor surface quality of machined workpieces. The adhesion of chips to the cutting edge of the tool often leads to tool fracture. In addition, tool breakage also occurs during cutting processes such as deep hole drilling, milling and threading, where it is difficult to supply the cutting fluid directly to the tool to the cutting interface. By employing surface texturing, the lubricant retained in the textures could help enhance the lubrication effects and thereby reducing the chance of tool breakage.

With optimum productivity, compatibility with workpieces and economic considerations, substantial research has been conducted on the improvement of machining methods or cutting tools. Many different parameters of cutting tools have been studied, such as geometry, surface coating and finishing. For example, diamond-like carbon (DLC) coated tools with very low friction are used for dry or near-dry aluminium alloys cutting [50], but in practice, a large amount of cutting fluid is required to avoid the adherence of aluminium chips to the tools with DLC coating [51]. Recent work indicates that dry machining can be enhanced by controlled surface texturing of cutting tools via improving friction conditions at the tool-chip and tool-workpiece interfaces [52].

Surface texturing improves the cutting performance of tools by reducing friction, wear, cutting forces and increasing shear angle. Texture patterns were applied on the rake and/or flank surfaces of cutting tools to allow more easy access for air or lubricant to the tool-chip and/or tool-workpiece interfaces, and further enhances the performance of machining operations. These surface textures can be beneficial in both wet and dry cutting conditions. In wet conditions, they store and provide cutting fluid at the point of cut, trapping wear debris and reducing contact at the tool/chips interface. Under dry conditions, they reduce the contact area between the tool and the chip and trap wear debris.

Enhanced tool performance depends on the optimization of texture geometry parameters such as texture width, the spacing between textures, texture shape and the orientation relative to the tool edge as well as the placement of the texture. The optimization will depend on the cutting conditions, the tool geometry, the cutting process, the workpiece material and the tool material. The choice of surface texture manufacturing technology for cutting tools should be based on whether it provides high dimensional accuracy and produces minimal surface damage.

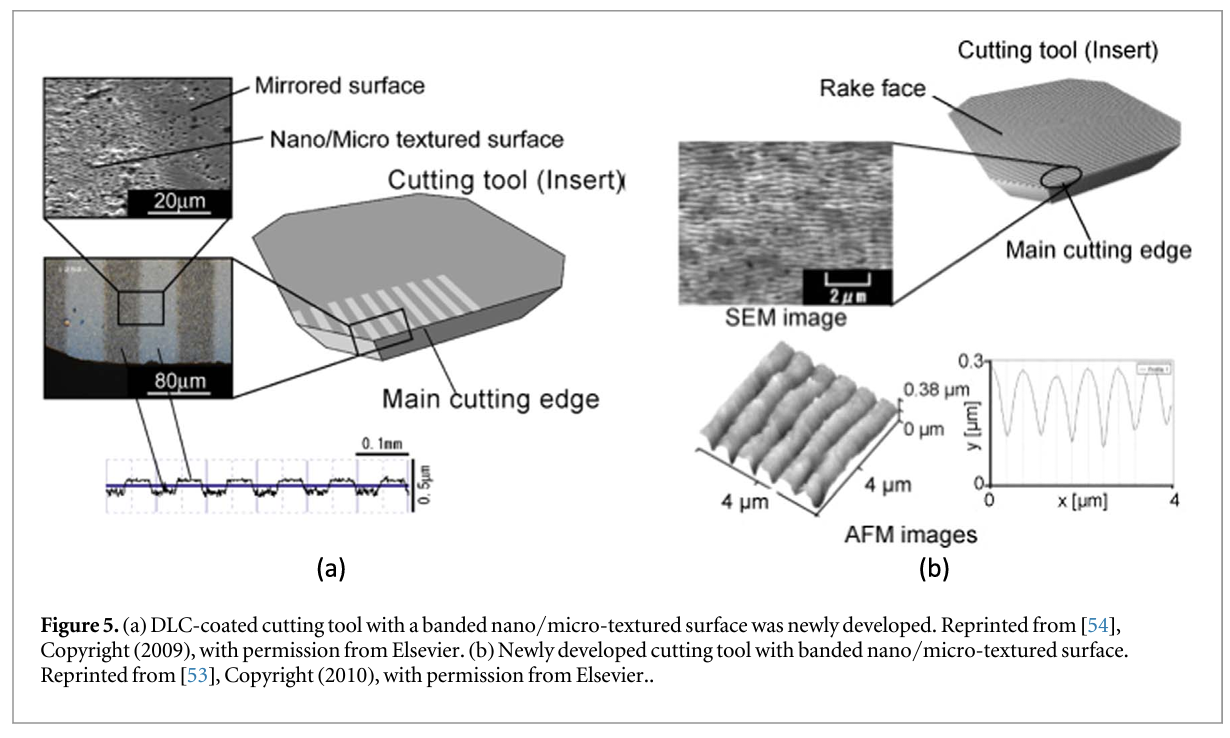

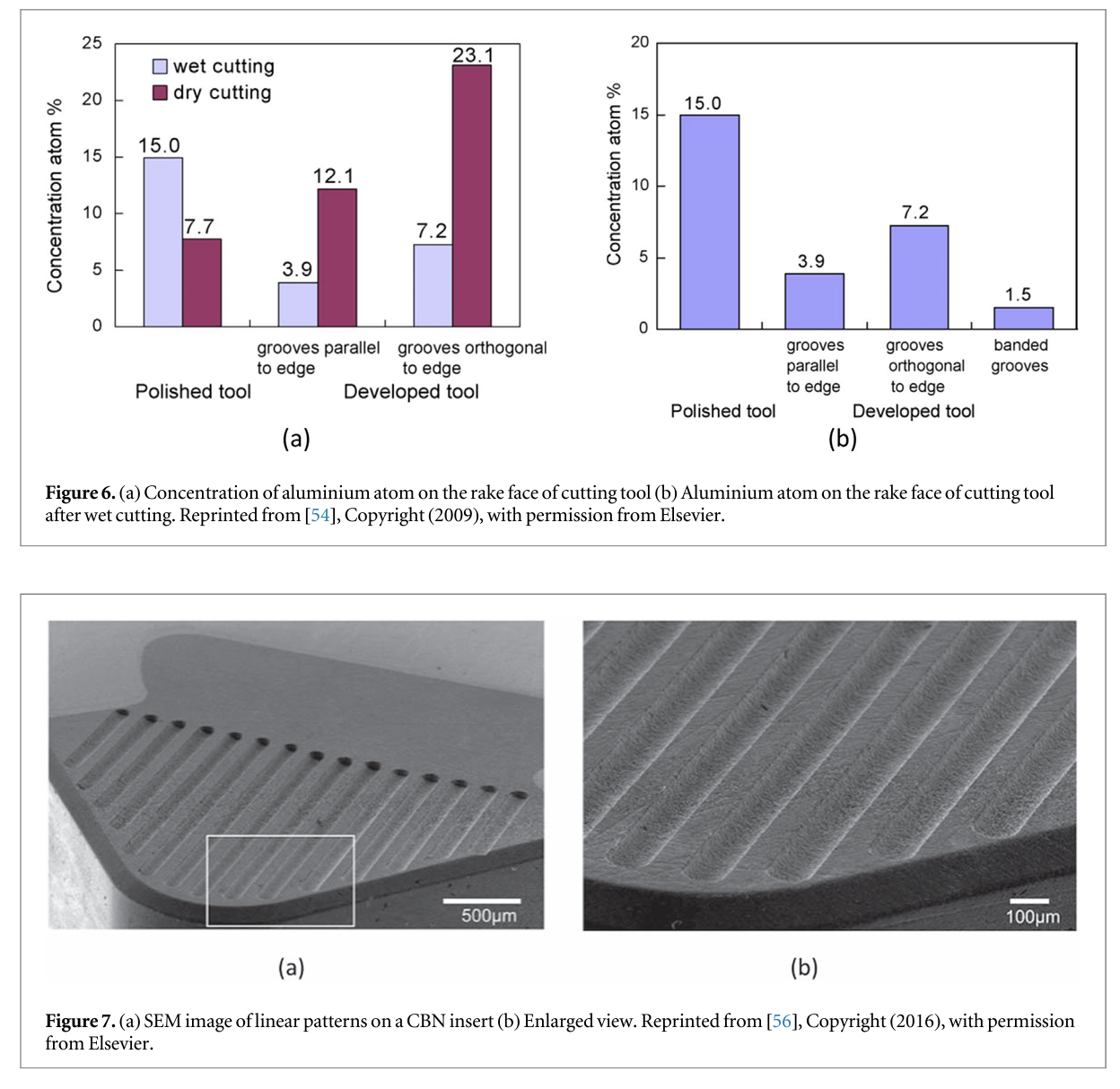

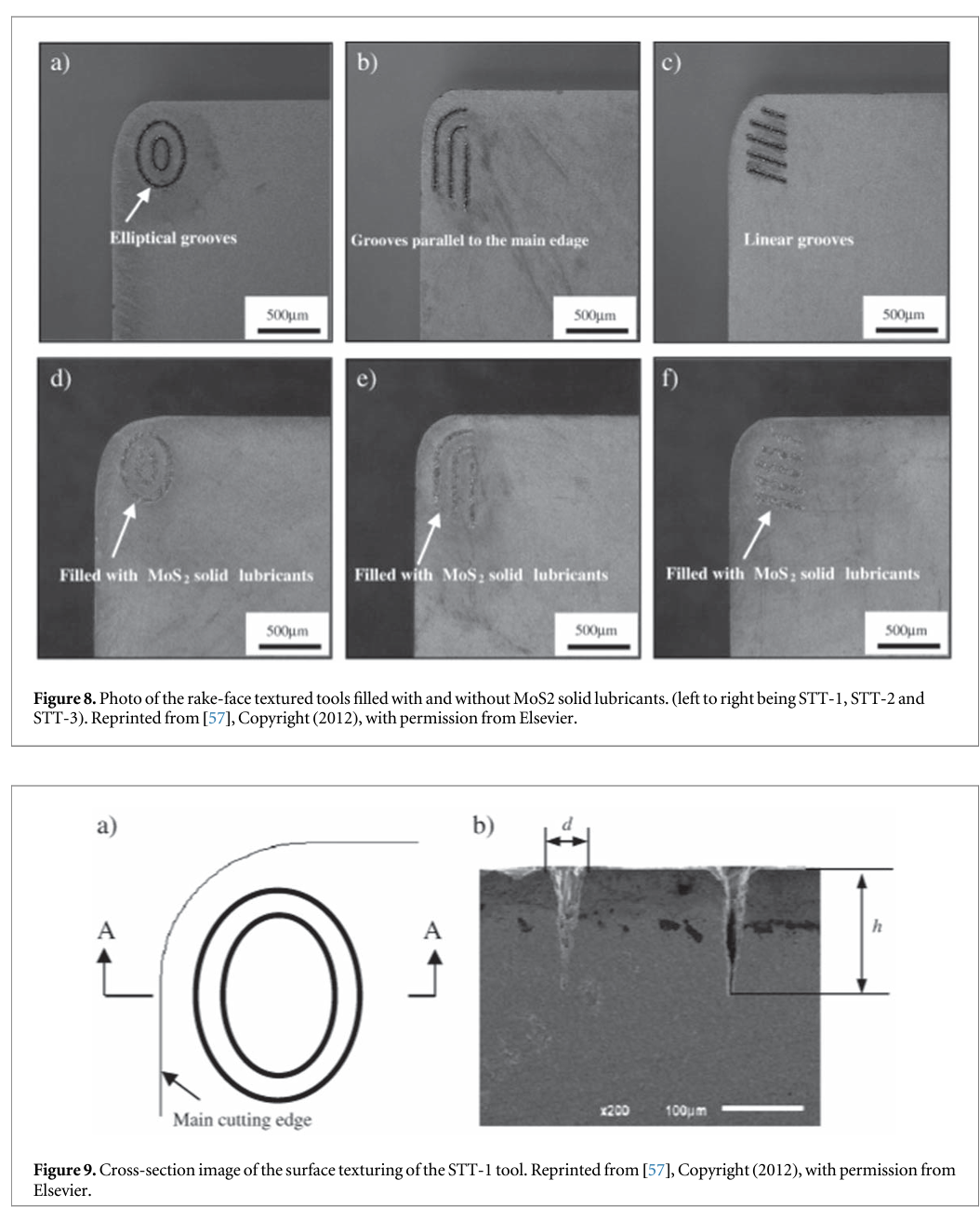

For example, linear grooved tools with texture parallel to the cutting edge have been found to reduce chip adhesion, thereby reducing friction and adhesive wear and providing better performance than perpendicular placed textures. Textures were suggested to be placed near the end of the cutting edge, rather than at the cutting edge directly, to avoid reducing the mechanical strength of the cutting tool. For example, nano/micro-textures with a depth of 100-150 nm and a spacing of 700 nm apart grooves were fabricated on the rake face of the DLC-coated cutting tool to improve the anti-adhesion effect in aluminium cutting, see figure 5. Adhesion in wet cutting was successfully reduced by improving the retention of the cutting fluid on the tool surface, and those with nano/microgrooves parallel to the main cutting edge have the most improved anti-adhesion properties [53]. However, the adhesion of aluminium chips to the surface during the dry cutting process was increased, see figure 6 [54]. In their following research on steel cutting, this approach was not successful and resulted in extremely high tool wear. Therefore, a new TiAlN-coated cutting tool with a periodically striated grooved surface was developed to overcome this problem. Surface milling experiments on steel showed that the new textured and coated tool has significantly reduced tool wear [55]. Kim et al also created grooved patterns (width: 110 //m, depth: 50 //m) on the rake face of the cubic boron nitride (CBN) tool, see figure 7, for machining AISI 52100 hardened steel under dry machining conditions. Under various feed rates, the micropattemed insert has reduced the cutting force by 2.7%-10.5% due to the reduced friction (9.5%-34.5% reduction according to calculation) [56].

Solid lubricant-filled textured tools offer higher performance in dry machining, thus avoiding the disadvantages of using cutting fluids. For example, the rake face of a WC/Co carbide tool was surface textured and filled with molybdenum disulfide (MoS2) solid lubricants, see figure 8. Dry cutting tests were performed with these rake face textured tools, which showed improved cutting performance compared to conventional tools. The rake face texture tool elliptical grooves (STT-1) shown in figure 9, showed the lowest cutting force, cutting temperature, and friction coefficient at the tool-chip interface of all the tools tested. It is suggested that this may be caused by the formation of a low-shear strength lubricating film at the tool-chip interface, which is released from the rake surface texture and smeared on the rake surface. Also, the reduced contact length of the tool-chip interface of a rake surface textured tool helps to reduce the direct contact area of the chips with the rake surface and also helps to reduced force and temperature [57]. Ona et al have also developed similar micro-level textures on the rake surface of ceramic tools for AISI 4340 machining with M0S2 lubricant Experimental tests were conducted with ver- tical/horizontal grooves and elliptical shaped textures (width: 200-215 //m, depth: 200-300 //m, gap: 150-222 //m) in chip flow directions, and they found that the vertical textured cutting inserts were most effective in reducing friction by up to 11.9% [58].

To sum up:

- For cutting tools, most researchers have used a joint type structure called a ‘groove’. But the optimum direction of groves is still under debit.

- The use of discontinuous textures on cutting tools still needs further investigation.

- Textured cutting tools can be beneficial in both wet and dry cutting conditions. The optimization of patterns/grooves depends on cutting conditions and workpiece/tool material.

- Surface texturing can be successfully used combined with coatings and solid lubricants.

- Piston ring & cylinder liner (PRCL)

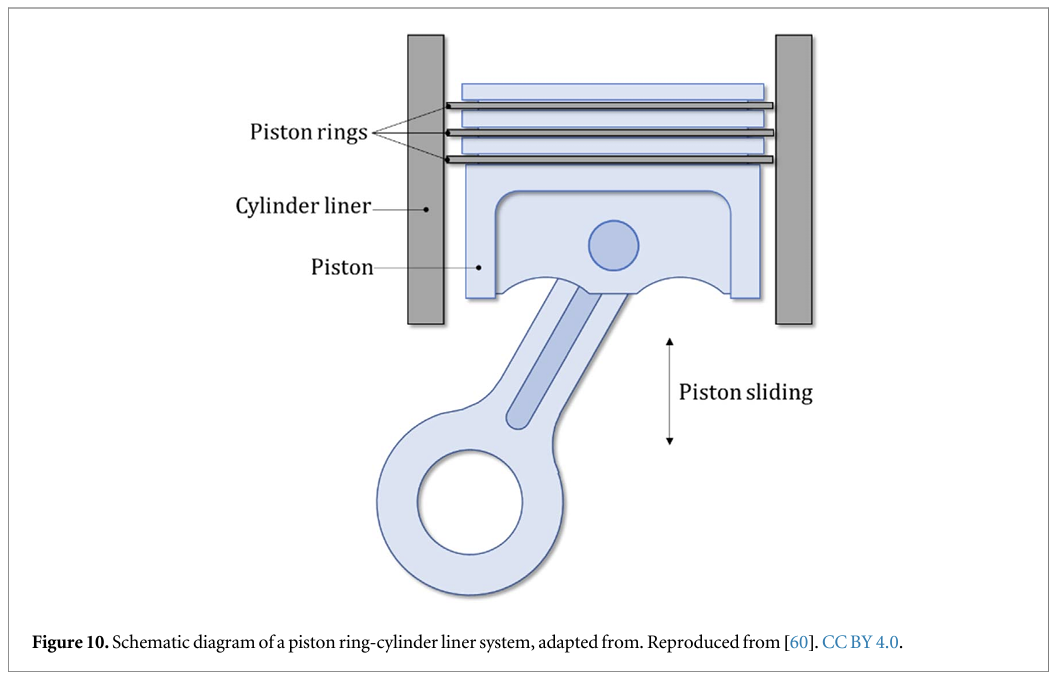

Internal combustion engine (IC) energy efficiency is of great concern in the pursuit of low emissions and environmental sustainability. In an internal combustion engine (ICE), the contact between cylinder liners and piston rings is a significant source of friction, accounting for about 45% of friction losses in engine systems [59]. The primary function of these rings is to prevent the combustion gas leaking from the combustion chamber to the crankcase. As shown in figure 0, a piston ring pack include compression rings and oil control ring. This section will discuss the contact between the cylinder liner and compression rings only.

Many factors can affect the tribological behaviour of the piston ring-cylinder liner interface, such as the face profile, width and the elasticity of the ring, the surface topography of both rings and liners, and the operating conditions [61]. During piston strokes, the reciprocating sliding motion between liner wall and piston ring is subject to experience the full range of lubrication regimes from boundary to hydrodynamic lubrication [62]. However, based on today*s engine power demands and high start-stop frequency, compression rings usually operate under mixed or boundary lubrication regimes [63]. Most of the friction loss and severe scuffing usually occur at the top dead-centres, where the sliding speed between PRCL is close to zero accompanied by the maximum combustion gas pressure and temperature [64,65].

The trend in the PRCL contact optimization has been directed by demands to reduce friction and wear without losing the sealing ability. In the process of optimizing the lubrication performance of PRCL contacts, methods of applying surface textures to cylinder liner wall or piston ring face were developed. Since the requirements of good sealing properties and optimal lubrication are contrary to each other, the demands on the topography of both components are strict [66].

3.2.1. Texturing on cylinder liner

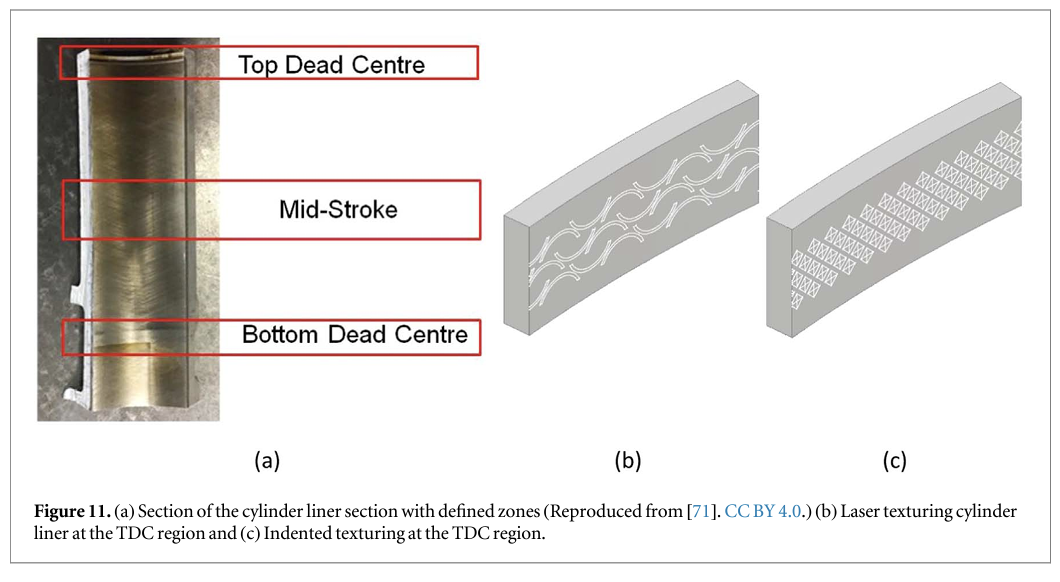

Cylinder liners can be made of cast iron, or steel or aluminium, and cast iron is the most common alloy used in larger engines’ cylinder liners [63]. Honing of the cylinder liner is the first extensive use of surface textures in mechanical components [3], and plateau- honed is still commonly used in today*s cylinder liners. Apart from honing, other texturing methods and features were also investigated, and fruitful results were obtained by Rahnejat’s group at Loughborough, UK. The work from this group focused on the texture effect at the reversal zone, where momentary cessation of motion and friction peak occur. Various texture shapes including semi-circular crescent, pyramid shape and chevon shape patterns were designed, optimized by numerical modelling. Then the optimized patterns were fabricated using laser etching or pyramid diamond indentation for tribometer testing or engine testing [67-70]. The reciprocating tribometer tests on chevon shape textures have shown that the lubricant supply is critical for the lubricant retained in the micro-reservoirs in the conjunctional inlet, thereby affecting the effectiveness of the micro-wedge effect [69]. Engine tests were conducted using a modified Honda CRF-450R engine to compare the performance of laser-etched semi-circular crescent textures (0.5 mm x 2 mm) and pyramid diamond indented patterns (124 pini x 124 pini), see figures 11(b) and (c). Both textures were only applied at the top dead centre (TDC) zone, see figure 11(a) for zones definition, and the rest of the liner were crosshatched. Both textured liners showed improved power against the non-textured benchmark liner. Laser- etched pattern performed better at low engine speed (5000-6300 REM), while the indented pattern gained more power at high engine speed (6300-9000 REM). They suggested the semi-circular crescent textures could provide a better lubricant reservoir effect and enhance the lubricant entrainment into the contact at low sliding speeds. While the semi-circular crescent textures would direct the flow away at high sliding speeds [68].

Other recent work by Vladescu et al discusses the effect of friction force reduction, lubricant film thickness variation and cavitation location for various patterns with a focus on piston-ring cylinder liner contacts [72]. It should be noted that these reciprocating tests were conducted with steel specimens and a fused silica specimen instead of liner material, to allow the observation of the cavitation phenomenon and film thickness measurement respectively. Compared to other texture shapes, the most significant friction reduction of up to 82% was observed when texture grooves were perpendicular to the sliding direction [73]. They suggested that the dimple length along the sliding direction should be smaller than the contact width. Otherwise, the friction may increase due to the lubricant film collapse [74]. Film thicknesses in a textured reciprocating contact operating in mixed lubrication regimes were measured, which evidenced the pockets act to increase the oil film thickness, thereby reducing the asperity contact and friction [75]. To achieve wear reduction, the dimple should be located immediately after the reversal point rather than directly at the point of reversal [76]. Also, the optimum size and distribution of dimples should be designed according to change in sliding velocity of the piston along the stroke. Deeper (depth: 8 )/ m)/dense (spacing: 500 )/m) features performed better under mixed and boundary regimes, while the shallower (depth: 3 )/m)/sparser (spacing: 3300 /im) features performed better at the transition between mixed and full film lubrication regimes [77]. This finding agreed well with the simulation results from Zhou [78].

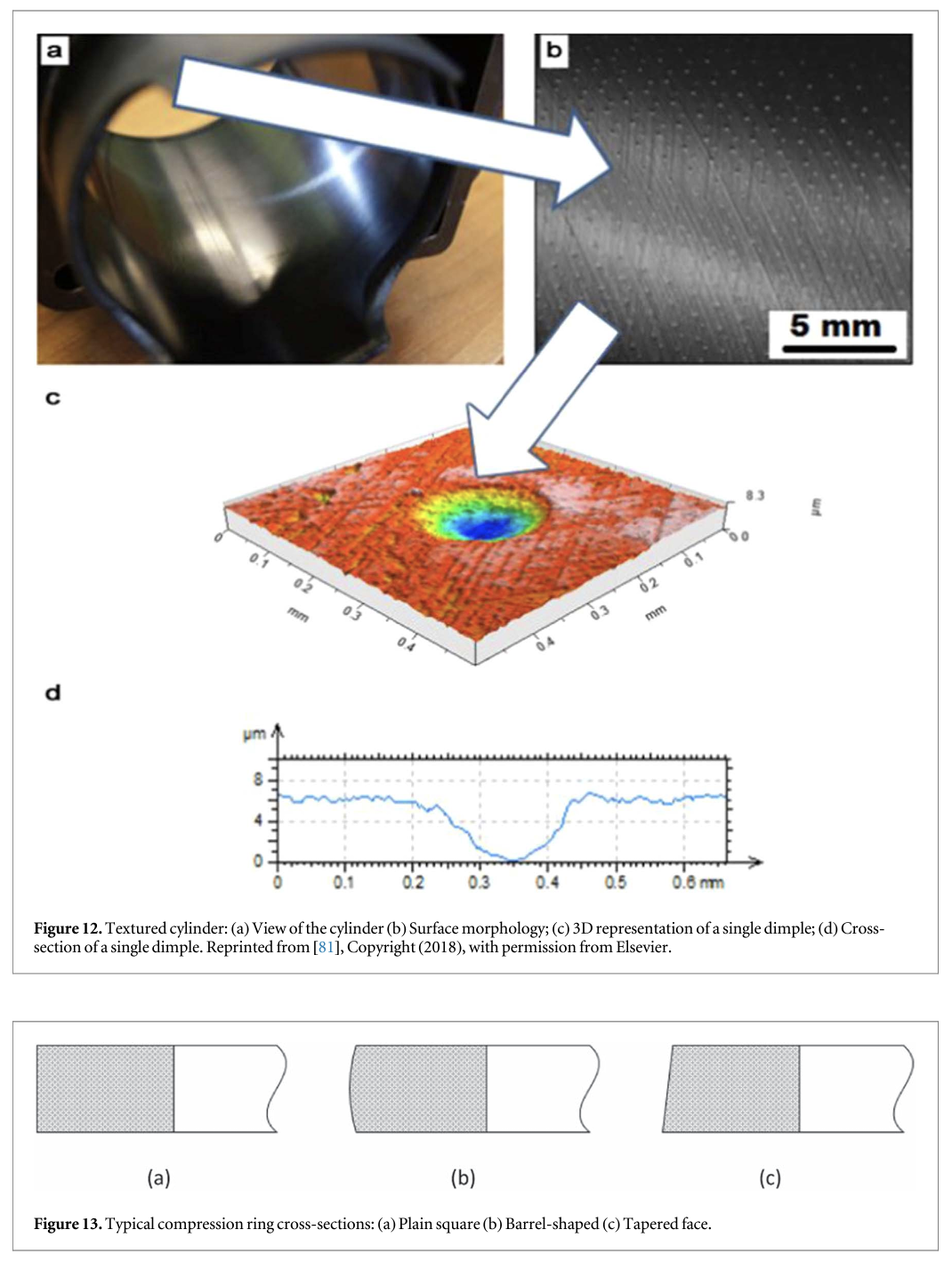

Some studies have also been conducted on the effect of circular textures distributed over the entire liner surface. From one mixed lubrication model for the contact between a flat piston ring and textured cylinder liner (without honing), hydrodynamic lubrication effect was effectively formed in most regions of the strokes, except near the dead points [79]. While other research showed that the performance of texture cylinder liner depends on the profile of piston ring, that the amount of friction reduction increases with the curvature of piston ring as the PRCL contact becomes more conformal [80]. More recently, in 2018, the combined effect of DLC coatings, honing and circular textures on one cylinder was tested by Koszela, see figure 12 [81]. The engine with a textured liner released a more responsive engine unit to cope with a higher peak power (5.8% increment) and higher maximum engine speed (RPM), which enables the motorbike to achieve higher racing performance. Besides, the broader and linear power band will also offer a better fuel efficiency since same engine output could be achieved under lower RPM.

In summary:

- Various textured shapes have proven effective as lubricant reservoirs in the top dead centre (TDC) and bottom dead centre (BDC) zone, and the volume of the dimples at this area plays an important role as it determines the amount of lubricant that can be retained and supplied to the contact.

- Textures size should be fully covered by the contact area to avoid lubricant film collapse or flow out of the contact.

- The combination of coating and surface texturing has been conducted successfully, and more work on this topic is likely to be of great interest in the future.

- Texturing on piston ring

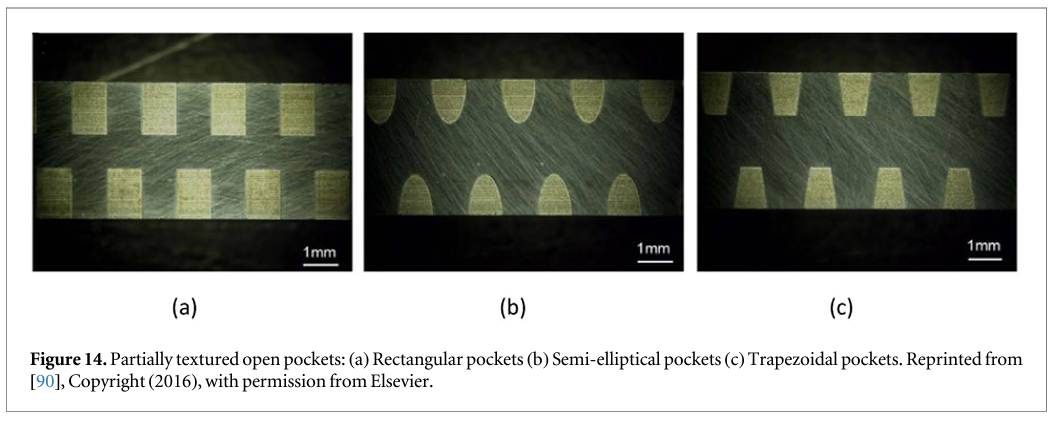

Piston ring material is selected in accordance with the requirements set by the operating conditions. Same with the piston liner, the piston rings are commonly made of cast iron. As cast iron can retain its original shape under heat, load, and other dynamic forces. The most typical compression ring cross-section shapes are plain square, barrel-shaped face and tapered face, see figure 13, with typical dimensions: diameter 45-150 mm and axial height around 1.5 mm.

The earliest and majority of texturing work on piston rings were conducted on the plain square configuration by Etsion’s group. In 2001, this group developed a model to study the potential use of microsurface structure in the form of micropores to improve tribological properties of a simplified ‘piston/cylinder’ system. They claimed that a friction reduction of 30% or even more is feasible with textured surfaces [82]. In the following year, experimental tests were conducted using a reciprocating tribometer to evaluate the theoretical results. Textures with optimised parameters from theoretical modelling (dimple diameter 100 /zm, dimple depth 10 /zm and area density 13%) were fabricated on the compression ring’s cylindrical free of a real ring/ liner pair. Good correlation was obtained with theoretical results that friction reduction of up to 30% was observed. However, the optimal parameters varied greatly between the different research groups, and Zavos’ modelling results showed that rectangular dimples with the depth of 4 pini, texture density of 61% and dimple length of 80 pini resulted in the best friction reduction of 50% [83]. Ryk suggested textures may behave detrimentally with deep dimples or high viscosity lubricant under certain working conditions (contact pressure: 0.5 MPa) [84]. A similar conclusion was also drawn by the later work of Bolander and Sadeghi [85], that only shallow dimples (1 //m) showed a beneficial effect under their test condition (contact pressure: 4.2-8.8 MPa), while deep dimples (10 //m) had detrimental effects.

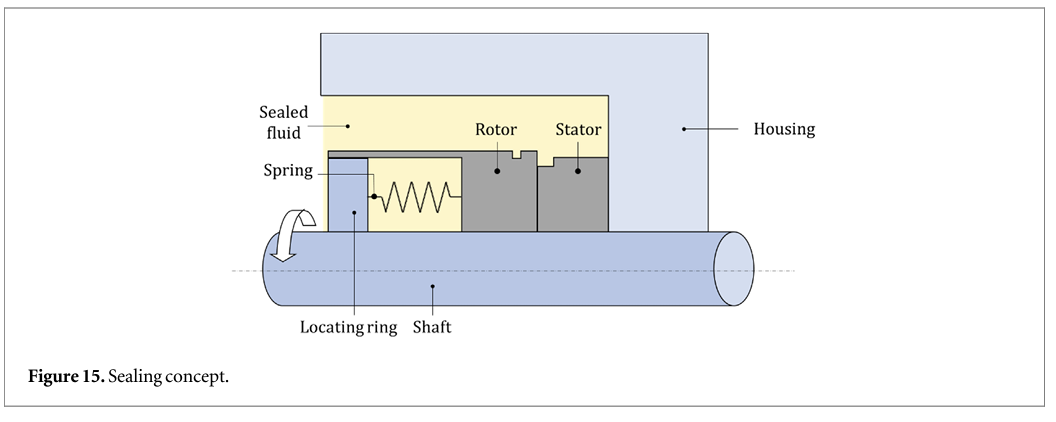

From 2005, Etsion’s group started their research of partially texturing on compressing rings through simulation, tribometer testing and engine tests [86]. The idea of using partially textured designs on piston rings came out from its successful use in mechanical seals. Simulation results by Tomanik also validated the benefits of using partially textured piston rings compared to the fully textured one [87]. From the reciprocating tribometer test, the use of optimized locally textured flat rings (symmetrically located textures at both axial ends of the piston ring) reduced friction by up to 25% compared to the fully textured and barrel-shaped untextured rings [86, 88]. More recently, dynamo-meter tests of the partially textured rings were carried out using a naturally aspired 2500 cm3 Ford Transit engine [89], and up to 4% (with repeatability within 0.5%) lower fuel consumption was achieved by using these partially-textured piston rings. The effects of partially texturing with ‘open pockets’ were also evaluated by Chen, see figure 14 [90, 91]. Similar with Etsion’s design, these pockets are also locating at both axial ends, the difference being that one of the pocket boundaries overlaps with the edges of the ring so that lubricant can flow directly into the pocket. Experimental results showed that the total friction between the cylinder liner and piston assembly dropped by 15% over a wide range of operating speed.

In very recent experimental research the combined effect of dimpled piston ring and lubricant additives have shown antagonistic effects during the formation of tribochemical films, that nullified the beneficial hydrodynamic effect generated by the textures [92]. Other recent work has dealt with laser surface texturing of the barrel-shaped ring [93, 94]. Different from the plain piston rings, only the centre of a barrel-shaped ring will be in contact with the liner surface. Therefore, the central dimple distribution presented a beneficial effect through simulation [94]. While the optimum texturing parameters will depend on the curvature of the ring, and the model need further experimental validation.

In summary:

- Both theoretical and experimental works have shown that deep dimples could be detrimental, especially at mixed to hydrodynamic lubrication regimes, while the depth value is dependent on the working conditions.

- Partially texturing a surface can generate ‘collective’ effect that is superior to fully textured piston rings. An attempt of using ‘open pockets’ was successfully made, and future research could look at its performance compared with ‘closed pockets’ that are located totally inside the piston ring face under the same running condition.

- Extra consideration should be taken when using surface texturing together with other lubrication enhancement techniques (like lubricant additives), as the effects might be conflicting.

- Texturing on the barrel-shaped ring has shown the potential for friction reduction through initial modelling, and it is still awaiting validation from experimental tests.

3.3. Mechanical seals

According to statistics in industrially advanced countries, the use of mechanical seals accounts for about 90% of all sealing device in rotary machines [95]. Mechanical seals are precision-engineered dynamic sealing product, which normally used to prevent leakage by forming a barrier between rotation and stationary components. As shown in a typical concept in figure 15, with proper design and installation, the rotating part rides on a thin lubricating film [96]. The resulting gap may increase the potential for leakage if the film is too thick. In contrast, the narrower clearance reduces leakage while torque increases. Therefore, the balance between torque and leakage needs to be considered according to specific applications [97].

Typical applications of mechanicals seals include pumps, compressors, turbines, propeller shafts, and aircraft engines. With the increasing demand for the use of mechanical seals in heavy-duty industrial applications, the need for performance (friction and leakage reduction), safety and component reliability under severe working conditions (high load, temperature and rotation speed) is growing [98]. Seals draw little attention when they are working properly, but significant problems arise as soon as they fail, such as the well-known fatal space shuttle challenger disaster caused by the failure of an О-ring seal. Other commonly seen consequences include the degradation of machine performance or even shut down due to thermal shock or short circuit; corrosion of components; unexpected pollution and so on. Therefore, the importance of the mechanical seal should never be underestimated during machine design, operation and maintenance.

A common material combination for the primary sealing surfaces is a hard material and a softer material, except for abrasive applications, where both faces frequently are hard. A wide range of materials is used for the hard face. For industries requiring high-performance mechanical seals, tungsten carbide as the hard- face material is commonly used. In recent years, the industry has gradually shifted from tungsten carbide to silicon carbide (SiC) owning to its comparatively good wear resistance and frictional properties, high thermal conductivity, and low density [99]. The soft face is usually carbon-graphite impregnated with resin or metal (e.g., antimony) to reduce porosity. Regardless of the face material, the running surfaces are often very flat and smooth, with a roughness (Ra) of approximately 0.1 pm [100].

Seals are one of the earliest and extensively studied applications of surface texturing under lubricated conditions. As mentioned earlier, the well-known modelling work by Hamilton which demonstrate that asperities can increase hydrodynamic pressure and load-carrying capacity was based on rotary-shaft seals [7]. Even the benefits of using textures on mechanical seals for leakage reduction were validated by Anno’s experimental work in 1969 [9], research in this field has laid dormant for around 30 years until the pioneering work carried out by Etsion’s group [1]. Their first paper published in 1996 has inspired hundreds or even thousands of research experiments around the world. And the use of surface texturing on mechanical seals provides at least eight types of benefits: increase load carrying capacity, fluid film stiffness, anti-seizer ability and wetting behaviour; reduced wear, friction, leakage and interface temperature [25]. In this section, the use of surface texturing in both liquid lubricated seals and gas seals are going to be discussed.

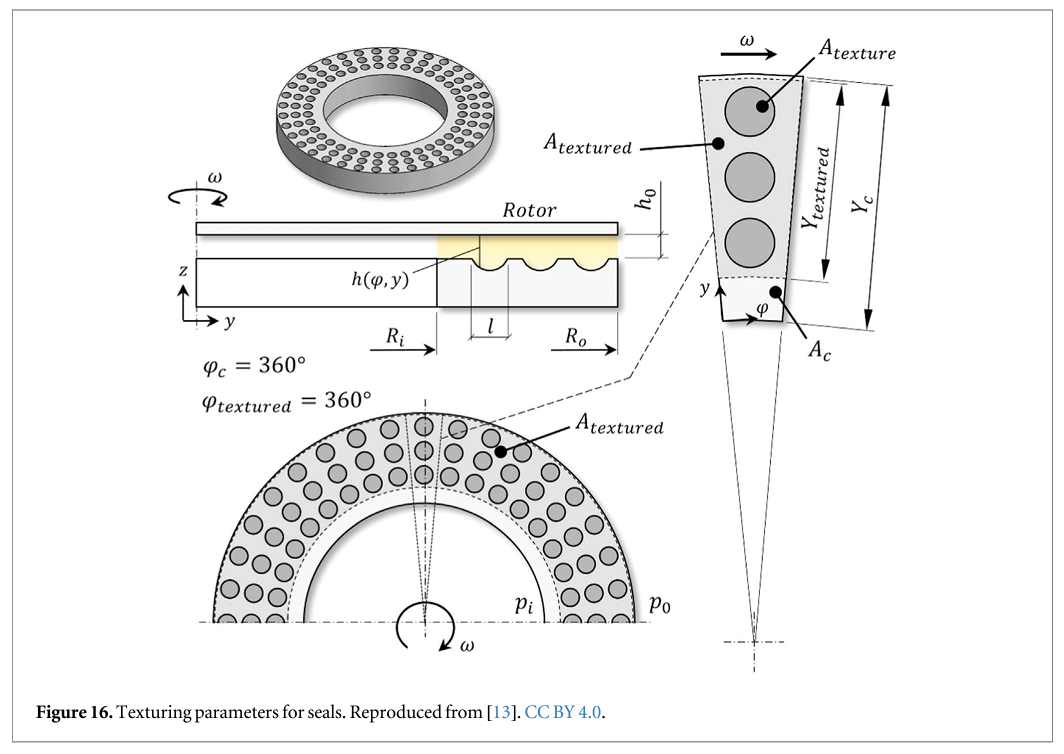

After the earlier simple modelling [1] established by Etsion’s group in 1996, more in-depth theoretical and experimental studies followed [101, 102]. Tests were conducted with dimpled SiC ring against carbon rings under water lubricated conditions, where hemispherical dimples textures diffused over part or the entire mating face of the SiC ring, see figure 16. Due to the greater surface separation and increased liquid film stiffness resulting from the increased hydrodynamic pressure, a reduction in both wear and frictional torque (up to 65%) has been observed, thereby the seal life was significantly extended. Similar results of friction and face temperature reduction were observed from the tests of textured SiC rings against carbon rings with oil lubrication [103]. Researchers suggested that the most significant parameter for optimum performance is the ratio of the dimple depth over diameter [25], which was named as the aspect ratio. Experiments from Qiu et al found that an aspect ratio of 0.138 (from range 0.06 to 0.2) is the optimum for reducing friction under various loads [104]. In 2003, Wang et al evaluated the anti-seizer ability of reactiveion etched silicon carbide (SiC) specimen in water lubrication using critical load, the load at which friction torque suddenly increases, as the index [105]. Their experiments showed that the friction level of textured samples was more stable than that of the untextured samples, and a maximum of more than 3 times increment of critical load was obtained with the deepest dimple design. One proposed reason is that these deep dimples could be more helpful in maintaining the gel film result from the tribochemical reactions between water and SiC ceramic, thereby reduced the friction and increase the anti-seizer ability. In case of using other material and liquid combination that do not react with each other, deep dimples may not be able to enhance anti-seizer ability.

Ma et al studied the effect of changing dimple diameter and depth along the radial surface [106, 107]. Although the advantages of sealing surfaces with varying dimple parameters have been seen from both experimental and theoretical studies, more work needs to be done on this subject for the optimal combination of dimples with various diameters and depths under different operating conditions. Other works by Chen etal used ultrashort-pulse LST to fabricate laser- induced periodic surface structures (LIPSS) on SiC mechanical seals, resulting in a coefficient of friction reduced by 20% [108]. However, the leakage rate has not been measured in their work, which is quite essential for sealing applications.

Shape effects of the micro-dimple in mechanical seals have been widely studied by both numerical modelling [101, 109, 110] and experimental testing [104, 111]. Siripuram’s numerical results suggest although dimple shapes do not play a significant role for friction coefficient, they have a significant influence on leakage rate and film thickness, and the triangular-shaped dimple has the smallest side leakage compared to other shapes (circular, diamond, square and hexagonal) [109]. However, the experimental investigation from Xie has shown that the triangularshaped dimples did present a significant difference compared to the circular dimples when the rotation direction is same with the converging direction of triangular shapes, which is attributed to the cavitation area and the hydrodynamic lift difference [111]. In recent work by Adjemout who looked triangularshaped textures [112-115], the actual shape of dimples was considered in modelling and validated by experiments. Due to the manufacturing technique, dimple profiles could differ from the theoretical designs. Results indicated that both dimple deformation and roughness inside dimples could significantly affect the seal performance. The height and orientation of roughness at dimples bottoms could impact the leakage level for a remarkable range of —75% to +96%. Therefore, to achieve accurate prediction, it is necessary to consider shape imperfections and defects caused by the manufacturing process and dimple deformation during the wear process.

The advantages of using surface texturing are not limited to liquid lubrication, hydrodynamic gas seals can also benefit from surface texturing [116,117]. In 2002, partially textured seal faces were developed by Etsion’s group to overcome the poor performance at high pressures [118]. Dimples were arranged on the high-pressure side of the seal face and leave the other side nontextured. Based on the optimum parameters for maximum seal efficiency based on load capacity and leakage considerations, a detailed parametric analysis of this partially textured type seal was performed by theoretical modelling [119,120]. An optimum textured length (textured portion/radial dimple column length — 0.7) and dimensionless dimple depth (dimple depth/seal clearance — 1.4) was found over a wide range operating condition. The experimental results also proved that the partial textured seal had a much higher carrying capacity and a lower friction torque (up to 40% reduction) compared to the non-textured seal. In addition, one of the textured seals operated for more than 10,000 h over a 38-month period before it was replaced, while a normal seal would have to be replaced four times over the same period [28]. They summarized that the main difference is the optimum dimple depth over diameter ratio, which is much smaller in a gas application than in a liquid application. In more recent studies, Xiaolei Wang’s group numerically demonstrated that elliptical dimples with a high area density (about 40%) can obtain a higher load-carrying capacity and higher gas film stiffness than grooves [121]. Compared to other conventional shapes (circles, ellipses, squares and triangles), the optimized asymmetric ‘V’ shapes provided higher load carrying capacity at the same leakage rate [98].

In summary:

- Surface texturing on the sealing face of the seal shows that partially textured surfaces generate improvement in terms of load-carrying capacity, friction and leakage performance.

- Shape deformation and roughness inside textures have a significant impact on friction and sealing performance, and they should be taken into consideration if more accurate and predictive modelling is to be achieved.

- Texture geometry optimization in a mechanical seal should not be limited to the conventional shapes, mixture or overlapped features with various geometries and scales may have great potential to achieve better sealing performance.

3.4. Journal bearing/Hydrodynamic bearing

Journal bearings are the most common support element for rotating machines that are subjected to radial loads. In internal combustion engines, they are used as the main support element for both crankshafts and camshafts. They are also used as load transfer elements for connecting rod crankshafts and piston assemblies. Multiple journal bearings are used in any engine configuration, and they account for 25% of all friction losses in the engine, or nearly 5% of fuel consumption [59].

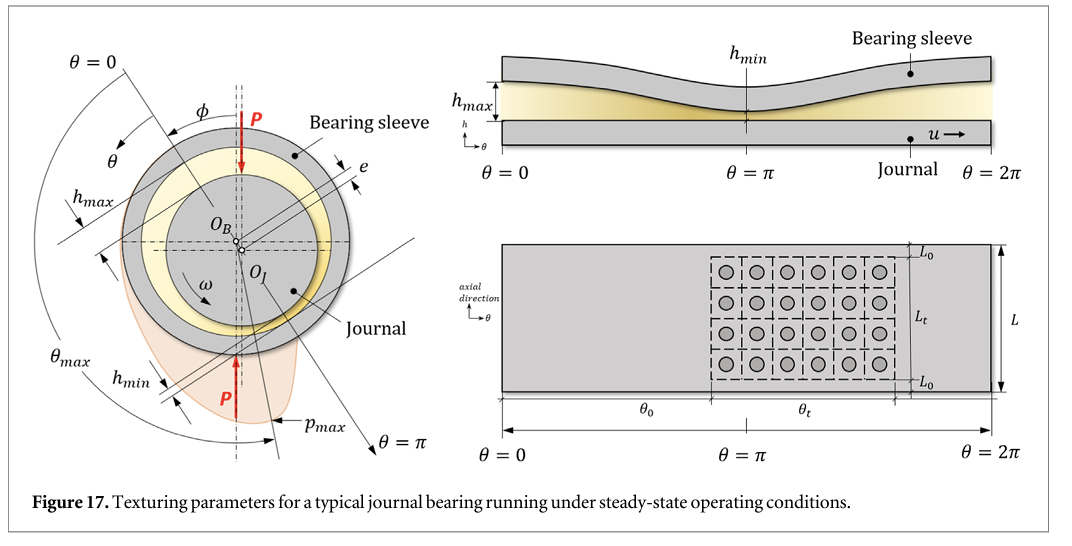

As shown in figure 17, a journal bearing only consists of three parts: a journal, a bearing sleeve and the lubricant between them. Journal, the rotation part, actually is part of the shaft rides inside the bearing. Since the whole purpose of the shaft is to transmit power in the machine, it is normally made of a high strength material such as alloy steel or stainless steel. Sometimes the journal section of the shaft gets additional treatment, such as chroming process, to improve its hardness and wear resistance. While the bearing sleeve is usually made of a soft bearing material such as copper alloy, aluminium alloy or, most commonly, babbitt (an alloy which is light-coloured and generally has a lead or tin base). It is a sacrificial component that protects the shaft if there is metal-to- metal contact between the sliding surfaces of the bearing. The soft sleeve can also allow foreign objects or contaminants in the lubricant to be embedded in itself, rather than scratching the shaft. The film thickness distribution against the angle is shown in figure L 7(b), that a converging zone is located just before Ѳ = тг.

One of the early studies focusing on the textured journal bearings was conducted by Talalghil et al and they established a numerical model of textured j ournal sleeves under steady-state operating conditions [122,123]. Parametric studies of spherical nests (size, depth, density) show that only proper texture design can produce beneficial results. The texture location study investigated the bearing performance of 25 different designs of bearing sleeves with the same texture arranged at different locations (fully textured, partially textured in one region and partially textured in multiple regions). The results show that full texturing leads to negative effects (27.2% decrease in minimum film thickness and 13.2% increase in frictional torque). The best performance was generated when textures locate between Ѳ = 185° and 230°, but the improvement is still minimal, with 1.8% increase in film thickness and 0.9% decrease in frictional torque.

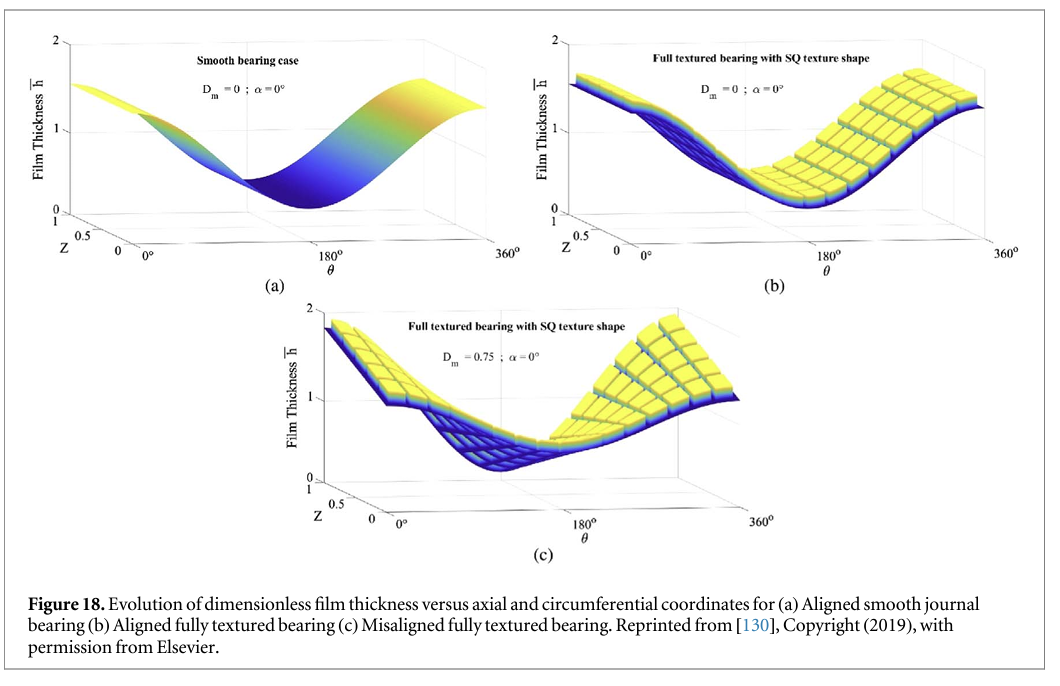

The non-dimensional parametric study on textured journal bearings by Brizmer and Kligerman showed that full texturing reduced the load capacity, while partial texturing can improve load capacity and attitude angle, but only limited to low eccentricity ratios cases. It should be noted that the texturing area is suggested to be arranged at the converging portion (between Ѳ = —20° and 140°) rather than in the diverging portion [124]. The study by Cupillard et al shows a positive effect of partially textured journal bearings. The implantation of textures either in the maximum pressure or maximum film zone can reduce the coefficient of friction or increase the carrying capacity, respectively [125,126]. Kango’s study also agreed with this finding that the optimal texturing zone is in the converging portion and especially at the maximum pressure region of the bearing. This will increase the load-carrying capacity compared to smooth and fully textured bearings [127, 128]. The following work by Zhang et al also suggested textures in the converging zone could maximize the interaction between the original convergence gap and dimples, and thereby improve the lubrication performance [129]. In the most recent studies conducted by Manser, multiple texture shapes and their effects on misaligned journal bearings were simulated, see figure 18, with Dm the degree of misalignment, and a the angle between ф and the rear centre of the misaligned journal. Results shown that the square texture appears to be the most favourable shape to improve the misaligned bearing performances [130,131].

However, a series of experiments conducted by Lu and Khonsari [132] compared the dimples effect of fully and partially textured journal bearing across different lubrication regime. Results have shown that both bearings exhibit similar friction under hydrodynamic lubrication regime. The fully textured bearing performs better than the partially textured one in mixed lubrication regime, which was attributed to more dimples in fully textured bearing served as lubricant reservoir for secondary lubrication effects. Engine tests with both fully textured and partially textured bearing liner were conducted by Vladescu [133]. His results show that fully textured bearing liner presents a substantial reduction in friction (approximately 18%), and the partially textured bearing with textures only applied outside the loaded region gives a friction reduction of up to 13%.

In summary:

- Surface texturing is mostly designed on the bearing liner of a journal bearing.

- The modelling results suggest that partial textures can help increase the minimum film thickness (to avoid asperity contacts in actual running), load carrying capacity and reduce friction; while fully textured bearings are useless, and the most recent modelling results suggest texture treatment in the convergence region.

- Experiments have shown the opposite, with fully textured bearings helping to reduce friction, and they even perform better than partially textured bearings.

- Textures have the potential to be successfully employed in journal bearings. More research is still needed to reveal the mechanisms behind enhanced performance and to aid agreement between modelling and experimental results.

4. Cases with detrimental tribological performances

Although surface texturing has been a great success in reducing friction and wear in a variety of applications, it should not be overlooked that some authors have concluded that textured surfaces exhibit a negative effect in certain cases, manifested by increased wear on textured part or/and the counter surfaces, increased friction and rolling contact fatigue. Those effects are detrimental to most mechanical applications.

Due to cost and flexibility considerations, texturing methods have limitations in terms of texture size, making it difficult to ensure that a single texture has characteristics that are smaller than the contact area, especially in non-conformal contacts. Inevitably, many lubrication systems will operate under extreme load and speed conditions that are not conducive to lubrication, such as the irregular contact that occurs in gears and rolling bearings. The application of surface patterns in non-conformal contacts under mixed lubrication, EHL or mixed EHL can result in a significant reduction in the resulting lubricant thickness and collapse of the lubricant film. This section will summarise these effects been observed.

4.1. Wear

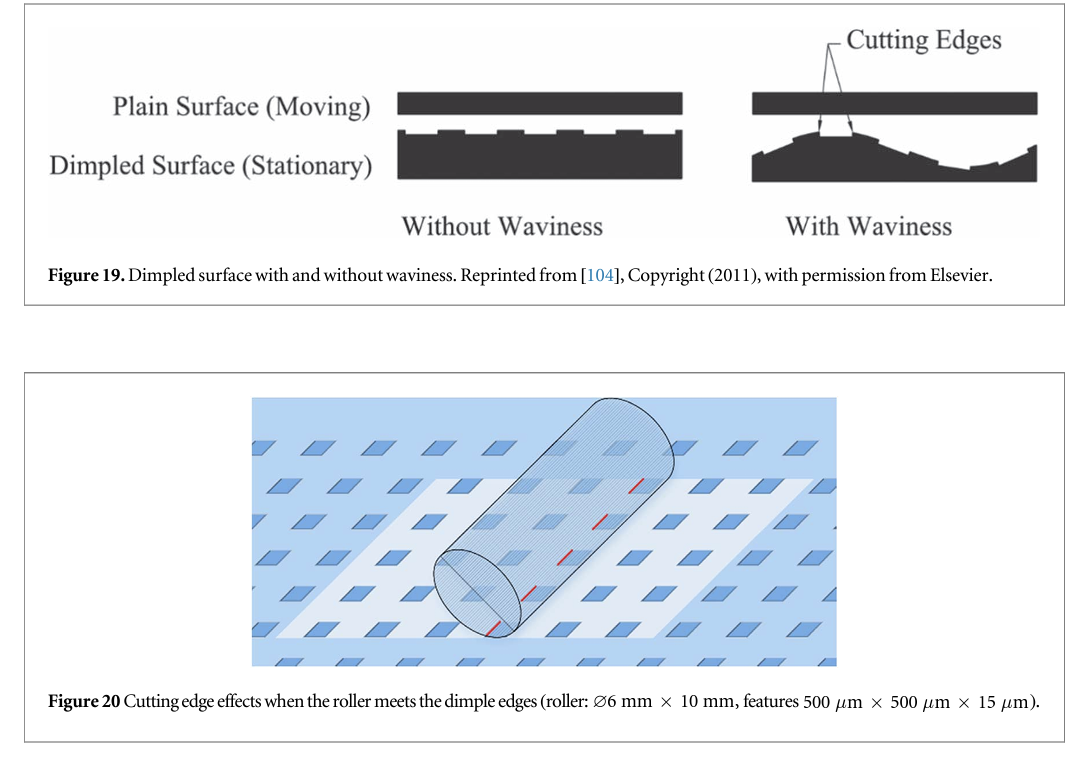

As early as 2003, Pettersson et al conducted a reciprocating test with a steel ball against coated textured surfaces under boundary lubrication conditions. Their results show that textured surfaces wear the ball more than a plain surface, and debris was accumulated in the textures [5]. Another experiment from Parreira showed that the textures did not survive under starvation lubrication and heavy load conditions resulting in minimal friction reduction [134]. In 2011, a series of experiments was conducted by Qiu to examine the tribological characteristics of a plain surface spinning against laser surface-textured rings samples. Although a reduction of friction was observed, a higher wear rate was observed from the plain surface compared to the bench test. The authors declared that due the thermally and mechanically induced surface waviness generated during the tests, the edge of the dimples may behave as ‘cutting edges’ that scratch the mating surface, see figure 19 [104].

This ‘cheese grater’ type of wear on the counterpart was also observed from the sliding tests conducted by Lu [18]. She found that when a steel roller was sliding against the textured plate in a reciprocating manner, the resulting wear scar on the roller had a clear periodic variation. Unlike Qiu’s experiment, this experiment was conducted with an initial line contact that the contact width is smaller than the dimple size. Thereby the ‘cutting edge’ effect was generated when the roller met the straight edge of the dimples, see figure 20, rather than from the waviness of textured dimples. Besides, the lubricant may escape from the

contact when textures are not fully covered by contact width because textures guide the lubricant away from the contact [20,135], which then lead to solid contact between tribo-pairs and increase the wear rate.

4.2. Friction

For line contact type reciprocating sliding tests, the friction reduction from texturing was only effective under boundary lubrication and mixed lubrication when the feature size is larger than the contact width, and higher friction was observed under full film lubrication regime by Lu et al [136,137]. According to observations from [74], under full film lubrication, the increased film thickness generated by the texture may lead to increased friction attributed to the increased shear rate [138]. Although the above experiments were all conducted by tribometer, they still suggest textures may not be applicable for sliding line contact type applications, such as the mid-stroke of piston-liner contact. Ryk suggests that deep dimples (20 //m) may have detrimental effects when working under certain operating conditions (contact pressure: 0.5 MPa or with high viscosity lubricants) [84]. Similar conclusions were reached by subsequent work by Bolander and Sadeghi, who showed that in their running conditions (contact pressure: 4.2-8.8 MPa), only shallow depressions (1 )/m) are beneficial, while deeper depressions (10 pirn) exhibited higher friction compared to the untextured sample [85]. A work involving experimental and numerical studies of individual pits inside EHL contacts shows that shallow pits greatly increase the thickness of the film, while deep pits lead to film collapse [139].

Another set of reciprocating sliding test conducted by Vilhena under boundary lubrication conditions showed that the textured surface always resulted in increased friction and increased wear for the case of initial point contact. For flat contacts, textured surfaces exhibit similar friction at low speeds. However, as the speed increases, the friction and wear rates of textured surfaces (especially for higher texture densities) are much higher than that for flat surfaces [140]. The results of Zum Gahr’s group also clearly show that the efficiency of the texture is highly dependent on the texture features and materials [141,142]. In their tests of ceramic/steel and ceramic/ceramic sliding pairs in distilled water, increased friction was observed when the cross-channel textured samples were tested under high loading conditions.

4.3. Fatigue

For other mechanical application involving repeated rolling/sliding motions under loaded conditions, like rolling elements bearings (REBs) and gear contacts, fatigue often occurs at the concentrated contacts [143]. From the conventional point of view, textured surfaces can bring the risk of rolling contact fatigue (RCF) due to the residual stresses induced by feature manufacturing and higher contact pressure from lower actual contact area [144]. And perfectly smooth surfaces, such as polished surfaces, should present optimal RCF life [145].

Based on the above, only a few experiments have been conducted on fatigue life enhancement by modified surface topography with non-conformal contacts. There is evidence that shallow dimples could be beneficial for RFC life enhancement under mixed lubrication conditions for shallower features (0.6 /im) [146-148].

While for deep features (1.45 /im), more asperity interaction and RCF life reduction were observed when the lubricant film thickness reduced or film collapse [148]. The modelling work of Zhai has shown that this improved fatigue performance may only be valid for mixed lubrication conditions [149]. Moreover, the residual stress or microstructural changes from intense plastic deformation (penning) or high temperature (LST) could also influence the RCF [146]. Research on the effects of fatigue is still ongoing and efforts should be redoubled to better understand it.

5. Conclusion and future works

This section summarizes the current knowledge and presents future trends regarding surface texturing applied to mechanical systems.

- An extensive array of experimental tests have been conducted. However, due to the lack of consistency in experimental methodology and measurements, it is very difficult to compare across different research groups, even for the same application. Besides, the reliability, repeatability and reproducibility of experimental tests need to be improved through systemic experimental design and advanced data analysis [150].

- Each application has unique solutions, most of them are experimentally derived. The texture behaviour should be tested and modelled to be integrated into the tribo-system. The texture designs need to be suitable for situations such as oil contamination, oxidation and misalignment and be designed to still provide beneficial effects. Otherwise, they will accelerate the wear process and or increase friction. Therefore, consideration should be given to make tests closer to the service condition of the applications reviewed.

- Texture has been shown to reduce friction (ranges from 10%-82%) in many cases, while in terms of wear and fatigue, textures only show minor enhancement or even detrimental effects due to cutting and stress concentrations from straight edges or sharp corners of the features. Under dry or boundary lubrication conditions, textures may promote adhesive wear processes, which should be

taken into extra consideration especially in high precision components. - The use of textures with other wear enhancement techniques (coatings, solid lubricant and lubricant additives) may be the way forward, however, it should be noted that textures may behave differently when combining with other techniques or lubricant additives.

- The relationship between the scale of features and the contact area is important. Surface texturing has shown beneficial effects in conformal contact type applications, the application in non-conformal contacts are still very challenging.

- Almost all the experimental tests were conducted with short-term durations. The long-term performance of textures still needs to be assessed for effective translation to products. From an economic point of view, the remaining useful life and costbenefit analysis need to be untaken to judge if the benefits from textures are valuable. In terms of sustainable developments, more effort should be focused on the suitable usage of surface texturing to reduce usage/consumption of hydrocarbon-based lubricants/pollution in mechanical applications [151].

- Modelling activity is essential to drive uptake of this technology, while most of the model validations were taken by comparing with other modelling work instead of experimental tests. Their reliability is still to be demonstrated and also modelling needs to consider the actual manufactured textures rather than the design surface and include lubricant decay such as water contamination, soot contamination, thermal degradation and additive depletion.

References

- Etsion I and Burstein L1996 A model for mechanical seals with regular microsurface structure Tribal. Trans. 39 677-83

- Gachot C, Rosenkranz A, Hsu S and Costa H 2017 A critical assessment of surface texturing for friction and wear improvement Wear372 21-41

- Martz L1949 Preliminary report of developments in interrupted surface finishes,’ Proa Inst. Meeh. Eng. 1611-9

- Kim E-S, Kim S-M and Lee Y-Z 2018 The effect of plateau honing on the friction and wear of cylinder liners Wear 400 207-12

- Pettersson U and Jacobson S 2003 Influence of surface texture on boundary lubricated sliding contacts Int. 36857-64

- Arslan A et al 2016 Surface texture manufacturing techniques and tribological effect of surface texturing on cutting tool performance: a review Rev. Solid State Mater. Sei. 41 447-81

- Hamilton D, Walowit J and Allen C1966 A Theory of Lubrication by Microirregularities Basic Eng. 88177-85

- Anno J N, Walowit J and Allen С1968 Microasperity Lubrication ofLubrication Tech. 90 351-5

- Anno J, Walowit J and Allen С1969 Load Support and Leakage from Microasperity-Lubricated Face Seals of Lubrication Tech. 91726-31

- Olver A, Fowell M, Spikes H and Pegg 12006 ‘Inlet suction’, a load support mechanism in non-convergent, pocketed, hydrodynamic bearings Inst. Meeh. Eng. Part J J. Eng. Tribal. 220105-8

- Fowell M, Olver A, Gosman A, Spikes H and Pegg 12007 Entrainment and Inlet Suction: Two Mechanisms of Hydrodynamic Lubrication in Textured Bearings Tribal. 129336-47

- Dobrica M, Fillon M, Pascovici M and Cicone T 2010 Optimizing surface texture for hydrodynamic lubricated contacts using a mass-conserving numerical approach Proa Inst. Meeh. Eng. Part J J. Eng. Tribal. 224 737-50

- Gropper D, Wang Land Harvey T J 2016 Hydrodynamic lubrication of textured surfaces: a review of modeling techniques and key findings Int. 94 509-29

- Kligerman Y, Etsion I and Shinkarenko A 2005 Improving tribological performance of piston rings by partial surface texturing J. 127632-8

- Saka N, Liou M J and Suh N P1984 The role of tribology in electrical contact phenomena Wear 100 77-105

- Bruce R W 2012 Handbook ofLubrication and Tribology, Volume II: Theory and Design, Second Edition (United States of America: CRC press)

- Tang Z, Liu X and Liu К 2017 Effect of surface texture on the frictional properties of grease lubricated spherical plain bearings under reciprocating swing conditions Proa Inst. Meeh. Eng. Part J J. Eng. Tribal. 231125-35

- Lu P, Wood R J, Gee M G, Wang L and Pfleging W 2018 A novel surface texture shape for directional friction control Lett. 6651

- WanY and Xiong D-S 2008 The effect of laser surface texturing on frictional performance of face seal J. Process. Technol. 197 96-100

- Costa H and Hutchings 12007 Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions Int. 401227-38

- Etsion 12013 Modeling of surface texturing in hydrodynamic lubrication Friction 1195-209

- Vend A, Ivanovic L, Stojanovic В and Svoboda P 2019 Surface texturing for tribological applications: a review SERBIATRIB ‘1916thlnt. Conf. Tribalpp227-39

- Grützmacher P G, Profito F J and Rosenkranz A 2019 Multiscale surface texturing in tribology—current knowledge and future perspectives Lubricants 795

- Costa H and Hutchings IM 2015 Some innovative surface texturing techniques for tribological purposes Inst. Meeh. Eng. Part]J. Eng. Tribol. 229429-48

- Ahmed A, MasjukiH, VarmanM, KalamM, Habibullah M and Al Mahmud К 2016 An overview of geometrical parameters of surface texturing for piston/ cylinder assembly and mechanical seals Meccanica 519-23

- Cobias D G, Fatu A, Maoui A and Hajjam M 2015 Manufacturing textured surfaces: state of art and recent developments Inst. Meeh. Eng. Part J J. Eng. Tribol. 229 3-29

- Etsion 12005 State of the art in laser surface texturing J. 127 248-53

- Etsion 12004 Improving tribological performance of mechanical components by laser surface texturing Lett. 17 733-7

- XingY, Deng J, WuZandChengH 2013 Effect of regular surface textures generated by laser on tribological behavior of SijNi/TiC ceramic Surf. Sei. 265 823-32

- Bonse J, Kirner S V, GriepentrogM, Spaltmann D and Krüger J 2018 Femtosecond laser texturing of surfaces for tribological applications Materials 11801

- Riveiro A, Ma^on A L, del Val J, Comesana R and Pou J 2018 ‘Laser surface texturing of polymers for biomedical applications Front. Phys. 616

- Mastud S, GargM, Singh R, Samuel and Joshi S 2012 Experimental characterization of vibration-assisted reverse micro electrical discharge machining (EDM) for surface texturing ASME2012 Int. Manufacturing Science and Engineering Conf, collocated with the 40th North American Manufacturing Research Conf, and in participation with the Int. Conf, on Tribology Materials and Processing (American Society of Mechanical Engineers Digital Collection) pp 439-48

- Byun J W, Shin H S, Kwon M H, Kim В H and Chu C N 2010 Surface texturing by micro ECM for friction reduction J. Precis. Eng. Manuf. 11747-53

- D’Urso G, Giardini C and Quarto M 2018 ‘Characterization of surfaces obtained by micro-EDM milling on steel and ceramic components The International Journal of Advanced ManufacturingTechnology97 2077-85

- Nakano M and Ando Y 2011 Recent studies on the application of microfabrication technologies for improving tribological properties Sei. 23 99-117

- Chae Y H 2007 Effect of size for micro-scale dimples on surface under lubricated sliding contact Key Eng. Mater. 345 765-8 Trans Tech Publ.

- Kim В H, Na C, Lee Y-S, Choi D and Chu C 2005 Micro electrochemical machining of 3D micro structure using dilute sulfuric acid 54191-4

- Kirchner V, Cagnon L, Schuster R andErtl G 2001 Electrochemical machining of stainless steel microelements with ultrashort voltage pulses Phys. Lett. 791721-3

- Hosseinabadi H N, Sajjady S and Amini S 2018 Creating micro textured surfaces for the improvement of surface wettability through ultrasonic vibration assisted turning The International Journal of Advanced Manufacturing Technology 962825-39

- Ramulu M 2005 Ultrasonic machining effects on the surface finish and strength of silicon carbide ceramics International Journal ofManufacturingTechnology Management 3

- Amanov A, Cho I, Pyoun Y, Lee C-S and Park 12012 Microdimpled surface by ultrasonic nanocrystal surface modification and its tribological effects Wear 286136-44

- Sreehari D and Sharma A К 2018 On form accuracy and surface roughness in micro-ultrasonic machining of silicon microchannels Eng. 53 300-9

- Xu S, Shimada K, Mizutani M and Kuriyagawa T 2014 Fabrication of hybrid micro/nano-textured surfaces using rotary ultrasonic machining with one-point diamond tool J. Mach. Tools Manuf 8612-7

- Qu N, Zhang T and Chen X 2018 Surface texturing of polyimide composite by micro-ultrasonic machining Mater. Eng. Perform. 271369-77

- Nakano M et al 2007 Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions Lett. 28131-7

- YamauchiY and KanzakiS 2002 Effect of workpiece properties on machinability in abrasive jet machining of ceramic materials Precis. Eng. 26193-8

- Townsend A, Senin N, Blunt L, Leach R and Taylor J2016 Surface texture metrology for metal additive manufacturing: a review Eng. 46 34-47

- PetterssonU and Jacobson S 2006 Tribological texturing of steel surfaces with a novel diamond embossing tool technique Int. 39 695-700

- Fletcher D,Kapoor A,SteinhoffKandSchuleitN 2000 Wear behaviour and surface form evolution of a novel titanium carbide implanted surface under lubricated conditions Inst. Meeh. Eng. Part J J. Eng. Tribol. 214 597-610

- BhowmickS and Alpas AT 2008 Minimum quantity lubrication drilling of aluminium-silicon alloys in water using diamond-like carbon coated drills J. Mach. Tools Manuf481429-43

- Yoshimura H et al2006 Study on near dry machining of aluminum alloys JSME International Journal Series C Mechanical Systems, Machine Elements and Manufacturing ' 83-9

- Dhage S B, Goindi G S, Jayal A D and Sarkar P 2013 Influence of Cutting Tool Flank Surface Texture In Mechanical Micromachining of AISI1045 Steel National Conf, on Manuf: Vision for Future, FIT Guwahati, Guwahati, India 81-89

- EnomotoT and SugiharaT 2010 Improving anti-adhesive properties of cutting tool surfaces by nano-/micro-textures 59597-600

- Sugihara T and Enomoto T 2009 Development of a cutting tool with a nano/micro-textured surface—improvement of anti-adhesive effect by considering the texture patterns Eng. 33425-9

- Enomoto T, Sugihara T, Yukinaga S, Hirose К and Satake U 2012 Highly wear-resistant cutting tools with textured surfaces in steel cutting 61571-4

- Kim D M, Lee I, Kim S K, Kim В H and Park H W 2016 Influence of a micropatterned insert on characteristics of the tool-workpiece interface in a hard turning process Mater. Process. Technol. 229160-71

- Jianxin D, Ze W, Yunsong L, Ting Q and Jie C 2012 Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes J. Refract. Met. Hard Mater 30164-72

- Orra К and Choudhury S К 2018 Tribological aspects of various geometrically shaped micro-textures on cutting insert to improve tool life in hard turning process Manuf. Processes 31502-13

- Holmberg K, Andersson P and Erdemir A 2012 Global energy consumption due to friction in passenger cars Int. 47 221-34

- Liu G, Lu Y-J, Zhang Y-F, Li 8 and Müller N 2017Numerical study on the lubrication performance of compression ringcylinder liner system with spherical dimples PLoS One 12 e0181574

- Nagar P andMiers S 2011 Friction between Piston and Cylinder of an IC Engine: a Review SAE 2011 World Congress & Exhibition 2011-01-1405

- Delprete C and Razavykia A 2018 Piston ring-liner lubrication and tribological performance evaluation: a review Proc Inst. Meeh. Eng. Part J J. Eng. Tribol. 232193-209

- Andersson P, Tamminen J and Sandstr"m C-E 2002 Piston RingTribology: A Literature Survey (Espoo: VTT Technical Research Centre of Finland)

- Zabala Bet al2017 Friction and wear of a piston ring/ cylinder liner at the top dead centre: Experimental study and modelling Tribal Int. 106 23-33

- Styles G, Rahmani R, Rahnejat H and Fitzsimons В 2014 Incycle and life-time friction transience in piston ring-liner conjunction under mixed regime of lubrication J. Engine Res. 15 862-76

- Lenthal J1996 Cylinder bore surface finish, its evolution and specification The Tribology of Internal Combustion Engines (United Kingdom of America: John Wiley and Sons Ltd)

- Rahnejat H, Balakrishnan S, King P and Howell-Smith S 2006 In-cylinder friction reduction using a surface finish optimization technique Inst. Meeh. Eng. Part D J. Automob. Eng. 2201309-18

- Howell-Smith S, Rahnejat H, King P D and Dowson D 2014 Reducing in-cylinder parasitic losses through surface modification and coating Proc Inst. Meeh. Eng. Part D J. Automob. Eng. 228 391-402

- Morris N, Leighton M, De la Cruz M, Rahmani R, Rahnejat H and Howell-Smith S 2015 Combined numerical and experimental investigation of the micro-hydrodynamics of chevron-based textured patterns influencing conjunctional friction of sliding contacts Proc Inst. Meeh. Eng. Part J J. Eng. Tribol. 229316-35

- Morris N, Rahmani R, Rahnejat H, King P and Howell-Smith S 2016 A numerical model to study the role of

surface textures at top dead center reversal in the piston ring to cylinder liner contact/. 138021703 - Bewsher S R, Leighton M, Mohammadpour M, Rahnejat H, Offner G and Knaus О 2019 Boundary friction characterisation of a used cylinder liner subject to fired engine conditions and surface deposition Tribal. Int. 131424-37

- Vlädescu S-C, Ciniero A, Tufail K, Gangopadhyay A and Reddyhoff T 2017 Looking into a laser textured piston ringliner contact Int. 115140-53

- Vlädescu S-C, Medina S, Olver A V, Pegg IG and Reddyhoff T 2016 The transient friction response of a laser-textured, reciprocating contact to the entrainment of individual pockets Lett. 6219

- Vlädescu S-C, Olver A V, Pegg IG and Reddyhoff T 2015 The effects of surface texture in reciprocating contacts—an experimental study Int. 82 28-42

- Vlädescu S-C, Medina S, Olver A V, Pegg IG and Reddyhoff T 2016 Lubricant film thickness and friction force measurements in a laser surface textured reciprocating line contact simulating the piston ring-liner pairing Int. 98 317-29

- Vlädescu S-C, Olver AV, Peg; IG andReddyhoffT 2016 Combined friction and wear reduction in a reciprocating contact through laser surface texturing Wear 358-359 51-61

- Vlädescu S-C, Ciniero A, Tufail K, Gangopadhyay A and Reddyhoff T 2018 Optimization of pocket geometry for friction reduction in piston-liner contacts Trans. 61 522-31

- Zhou Y, Zhu H, Tang W, Ma C and Zhang W 2012 Development of the theoretical model for the optimal design of surface texturing on cylinder liner Int. 521-6

- YinB, LiX, FuY and Yun W 2012 Effect of laser textured dimples on the lubrication performance of cylinder liner in diesel engine Sei. 24 293-312

- Checo H M, Ausas R F, Jai M, Cadalen J-P, Choukroun F and Buscaglia G C 2014 Moving textures: simulation of a ring sliding on a textured liner Int. 72131-42

- Koszela W, Pawlus P, Reizer R and Liskiewicz T 2018 The combined effect of surface texturing and DLC coating on the functional properties of internal combustion engines Tribal. Int. 127470-7

- Ronen A, Etsion I and Kligerman Y 2001 Friction-reducing surface-texturing in reciprocating automotive components Trans. 44 359-66

- Zavos A В andNikolakopoulos P G 2015 Simulation of piston ring tribology with surface texturing for internal combustion engines Sei. 27151-76

- Ryk G, Kligerman Y and Etsion 12002 Experimental investigation of laser surface texturing for reciprocating automotive components Tribal Trans. 45 444-9

- Bolander N W and Sadeghi F 2006 Surface modification for piston ring and liner IUTAM Symp. on Elastohydrodynamics and Micro-elastohydrodynamics (Berlin) (Springer) pp 271-83

- Ryk G, Kligerman Y, Etsion I and Shinkarenko A 2005 Experimental investigation of partial laser surface texturing for piston-ring friction reduction Trans. 48 583-8

- Tomanik E, Profite F J and Zachariadis D C 2013 Modelling the hydrodynamic support of cylinder bore and piston rings with laser textured surfaces Int. 59 90-6

- Ryk G and Etsion 12006 Testing piston rings with partial laser surface texturing for friction reduction Wear 261792-6

- Etsion I and Sher E 2009 Improving fuel efficiency with laser surface textured piston rings Int. 42542-7

- Shen C and Khonsari M 2016 The effect of laser machined pockets on the lubrication ofpiston ring prototypes Tribal Int. 101273-83

- Shen C and Khonsari M 2016 Tribological and sealing performance of laser pocketed piston rings in a diesel engine Tribal. Lett. 64 26

- Mishra P and Ramkumar P 2019 Effect of additives on a surface textured piston ring-cylinder liner system Tribology- Materials, Surfaces & Interfaces 13 67-75

- Liu C, Lu Y, Zhang Y, Tang L, Guo C and Müller N 2019 Investigation on the frictional performance of surface textured ring-deformed liner conjunction in internal combustion engines Energies 12 2761

- Gadeschi G B, Backhaus К and Knoll G 2012 Numerical analysis of laser-textured piston-rings in the hydrodynamic lubrication regime J. 134041702

- Wei L, Gu B, Feng X and Sun J 2009 Research on friction characteristic of end faces of mechanical seals Advanced Tribology (Berlin: Springer) pp 304-8

- Denny D1961 Some measurements of fluid pressures between plane parallel thrust surfaces with special reference to radial-face seals Wear4 64-83

- Lebeck AO 1991 Principles and Design ofMechanical Face Seals (New York: Wiley)

- WangX, Shi L, Dai Q, Huang Wand Wang X 2018 Multiobjective optimization on dimple shapes for gas face seals Int. 123 216-23

- Dietzel W and Vasko J 2015 The evolution and application of mechanical seal face materials Proa of the 31st Int. Pump Users Symp. (Turbomachinery Laboratories, Texas A&M Engineering Experiment Station)

- Bhushan В 2000 Modem Tribology Handbook, TwoVolume Set (Boca Raton: CRC press) (https://doi.org/10.1201/9780849377877)

- Etsion I, Kligerman Y and Halperin G1999 Analytical and experimental investigation of laser-textured mechanical seal faces Trans. 42511-6

- Etsion 12000 Improving tribological performance of mechanical seals by laser surface texturing Proc, of the Int. Pump Users Symp. pp 17-22

- YuX,HeS and Cai R 2002 Frictional characteristics of mechanical seals with a laser-textured seal face Mater. Process. Technol. 129463-6

- Qiu Y and Khonsari M 2011 Experimental investigation of tribological performance of laser textured stainless steel rings Int. 44 635-44

- Wang X and Kato К 2003 Improving the anti-seizure ability of SiC seal in water with RLE texturing Lett. 14 275-80

- Ma C, Li D, Sun J, Yu Q and Duan Y 2018 Investigation on performance of mechanical seal with varying dimple depth along the radial face Recent Patents on Mechanical Engineering 1176-84

- Ma C, Gu W, Tu Q, Sun J and Yu В 2016 Experimental investigation on frictional property of mechanical seals with varying dimple diameter along the radial face Advances in Mechanical Engineerings 1687814016664837

- Chen C-Y etal 2012 Microstructure and lubricating property of ultra-fast laser pulse textured silicon carbide seals Phys. A107 345-50

- Siripuram R В and Stephens L S 2004 Effect of deterministic asperity geometry on hydrodynamic lubrication J. 126 527-34

- Meng X, Bai S and Peng X 2014 Lubrication film flow control by oriented dimples for liquid lubricated mechanical seals Int. 77132-41

- Xie Y, Li Y, Wang Y, Suo S and Liu X 2014 An experimental investigation of tribological performance of triangular textures in water lubrication regime Science China Physics, Mechanics and Astronomy 57 273-9

- Adjemout M, Brunetiere N and Bouyer J 2015 Numerical analysis of the texture effect on the hydrodynamic performance of a mechanical seal Surface Topography: Metrology and Properties 1014002

- Adjemout M, Brunetiere N and Bouyer J 2018 Friction and temperature reduction in a mechanical face seal by a surface texturing: comparison between TEHD simulations and experiments Trans. 611084-93

- Adjemout M, Andrieux A, Bouyer J, Brunetiere N,

- Marcos G and Czerwiec T 2017 Influence of the real dimple shape on the performance of a textured mechanical seal Tribol. Int. 115409-16

- Adjemout M, Brunetiere N and Bouyer J 2015 Optimization of mesh density for numerical simulations of hydrodynamic lubrication considering textured surfaces Proa Inst. Meeh. Eng. Part J J. Eng. Tribol. 2291132-44

- Kligerman Y and Etsion 12001 Analysis of the hydrodynamic effects in a surface textured circumferential gas seal Trans. 44472-8

- McNickle A and Etsion 12004 Near-contact laser surface textured dry gas seals Trib. 126 788-94

- Etsion I and Halperin G 2002 A laser surface textured hydrostatic mechanical seal Trans. 45 430-4

- Feldman Y, Kligerman Y, Etsion I and Haber S 2006 The Validity of the Reynolds Equation in Modeling Hydrostatic Effects in Gas Lubricated Textured Parallel Surfaces Tribol. 128345-50

- Feldman Y, Kligerman Y and Etsion 12007 Stiffness and Efficiency Optimization of a Hydrostatic Laser Surface Textured Gas Seal J. 129407-10

- Shi L, WangX, SuX, HuangW andWangX 2016 Comparison of the load-carrying performance of mechanical gas seals textured with microgrooves and microdimples Tribol. 138021701

- Tala-Ighil N, Maspeyrot P, Fillon M and Bounif A 2007 Effects of surface texture on journal-bearing characteristics under steady-state operating conditions Proa Inst. Meeh. Eng. Part J J. Eng. Tribol. 221623-33

- Tala-Ighil N, Fillon M and Maspeyrot P 2011 Effect of textured area on the performances of a hydrodynamic journal bearing Int. 44 211-9

- Brizmer V and Kligerman Y 2012 A laser surface textured journal bearing/. Tribol. 134031702

- Cupillard S, Glavatskih S and Cervantes M 2008 Computational fluid dynamics analysis of a journal bearing with surface texturing Proa Inst. Meeh. Eng. Part J J. Eng. Tribol. 22297-107